CNC Handheld Fiber Laser Welding Machine

Parameters Master control system: PLC Power supply: 380V±10%, 50Hz, 40A Wavelength: 1064nm Power required: 15kW, three-phase Performance parameter:

Welding thickness: Power / Material weld depth(mm) 0 0.75 1.5 2.25 3 3.75 4.5 5.25 500W Mile Steel Stainless Steel Galavinised Steel 750W Mile Steel Stainless Steel Galavinised Steel 1000W Mile Steel Stainless Steel Galavinised Steel 1500W Mile Steel Stainless Steel Galavinised Steel 2000W Mile Steel Stainless Steel Galavinised Steel Characteristics of the laser weld technology:  Fast speed, high depth and almost no deformation. Workers can weld in a confined space with special conditions. Can weld the materials that are difficult to melt, such as titanium and quartz. High power density after laser being focused. When high power workpiece welding, width-depth ratio can be 5:1, tiptop can be up to 10:1. Can be used for small parts and fine structures. The laser beam is focused to a light and makes accurate positioning which can be used in mass production or a small piece in the group of welding. Can weld the inaccessible areas with great flexibility.

Fast speed, high depth and almost no deformation. Workers can weld in a confined space with special conditions. Can weld the materials that are difficult to melt, such as titanium and quartz. High power density after laser being focused. When high power workpiece welding, width-depth ratio can be 5:1, tiptop can be up to 10:1. Can be used for small parts and fine structures. The laser beam is focused to a light and makes accurate positioning which can be used in mass production or a small piece in the group of welding. Can weld the inaccessible areas with great flexibility.

| Model | PS1000 | PS1500 |

| Laser type | Continuous impulse | |

| Laser wavelength | 1070nm | |

| Max. laser power | 1000W | 1500W |

| Range of adjustable power | 1-100% | |

| Repeat frequency | 5-10KHz(adjustable) | |

| Pulse width | Continuous light | |

| Welding depth | ≤1.2mm | |

| Repeat precision | ±0.01mm | |

| Power stability | ±2% | |

| Service medium | Rare earth doped fiber | |

| Length of fiber-optical | 10m(standard) | |

| Beam quality | Single mode/multi mode | |

| Interface of fiber-optical | QBH | |

| Module life | >100000hrs | |

| Cooling style | Water cooling | |

| Power consumption | 6KW | |

| Power supply | 220V±10%/50HZ/30A 380V±10%/50HZ/30A | |

Compared with the traditional welding technology, laser welding technology has competitive characteristics as follows:

Scan QR to Read

Links:https://globefindpro.com/products/5166.html

Links:https://globefindpro.com/products/5166.html

Recommended Products

-

Hydraulic Corner Notching Machine, Variable Angle with Punch

Hydraulic Corner Notching Machine, Variable Angle with Punch

-

Professional Powder Coating Machine COLO-191S-V

Professional Powder Coating Machine COLO-191S-V

-

Fiber Laser Cutting Machine, Open-bed Type

Fiber Laser Cutting Machine, Open-bed Type

-

CNC Servo Electro-Hydraulic Press Brake, with DELEM DA52S Controller

CNC Servo Electro-Hydraulic Press Brake, with DELEM DA52S Controller

-

CL-191S Automatic Powder Coating Gun System

CL-191S Automatic Powder Coating Gun System

-

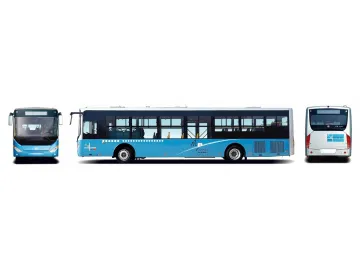

Hydrogen Fuel Cell Electric Bus

Hydrogen Fuel Cell Electric Bus

-

Hydraulic Press Brake with E21 Controller

Hydraulic Press Brake with E21 Controller

-

Fiber Laser Cutting Machine with Tube Cutting, Enclosed Type

Fiber Laser Cutting Machine with Tube Cutting, Enclosed Type

-

Fashion

Fashion

-

Hydraulic Press Brake with E200P Controller

Hydraulic Press Brake with E200P Controller

-

3-Roller Hydraulic Roll Bending Machine

3-Roller Hydraulic Roll Bending Machine

-

Electrostatic Powder Coating Equipment Manufacturer

Electrostatic Powder Coating Equipment Manufacturer

Hot Products