UV Flatbed Printer, WLD-UV4590

To satisfy ever changing market demands, WLD continuously designs and produces new UV flatbed printing machines, including the WLD-UV4590. As a small format UV flatbed printer, its size is equal to that of an A2 flatbed printer. This printer offers a 1440 DPI printing, as well as consistent quality. Typical materials this printer can print on include acrylic, aluminum composite panels, wood boards, foam bricks, metal plates and paper. If required, the UV4590 digital printing machine can be equipped with Ricoh GH2220 or Epson Dx7 print head for consistent printing quality.

Technical Parameters

| Print head | Epson DX7 | Ricoh GH2220 | ||||

| Number of print head | 1-2 | 4-16 | ||||

| Ink dot size | 3.5PL | 3PL | ||||

| Printing speed | Sketch mode | 36 m2/h | 48 m2/h | |||

| Production mode | 24 m2/h | 28 m2/h | ||||

| High quality mode | 14 m2/h | 14 m2/h | ||||

| Media | Types | Acrylic, aluminum composite panels, wood boards, ceramic tiles, foam boards, metal plates, paper, etc. | ||||

| Thickness | 160mm | 120mm | ||||

| Weight | 15KG | 100KG | ||||

| Printing area | 450mm×900mm | 2500mm×1900mm | ||||

| Ink types | Epson ink, 4 or 6 colors, white ink | Ricoh GH2220 ink, 4 or 6 colors, white ink | ||||

| Cleaning method | Siphon | Positive pressure | ||||

| LED-UV lamps | Water cooling, UV lamps, 480W | Water cooling, UV lamps, 600W | ||||

| Power supply | AC200V, main engine, 1000W LED-UV lamps, 480W Vacuum motor, 1500W | AC200V, main machine, 1000W LED-UV lamps, 1200W Vacuum motor, 1500W | ||||

| Technical support | Protective cover | UV plate to isolate UV ray and protect eyes | ||||

| Data interface | USB3.0 | |||||

| RIP software | PHOTOPRINT, MainTop, Recolor, color gate | |||||

| Image format | TIFF, JPEG, POSTSCRIPT3, EPS, PDF | |||||

| Color control | Compliant with ICC standard, with curve and density adjustment function | |||||

| Print head technology | drop ON DEMAND micro-pressure electric printing | |||||

| Printing mode | One-direction, dual-direction | |||||

| Working environment | Temperature: 20-28 ℃ Humidity: 40%-60% | |||||

| Printing resolution | 360×720/720×720/1440×720 | 300×300/600×600/1200×1200 | ||||

| Machine size | L 1100mm× W 1130mm× H 770mm, 130kg | L 4020mm× W 2750mm× H 1260mm, 1350kg | ||||

| Packaging size | L 1270mm× W 1250mm× H 990mm, 180kg | L 4250mm× W 3050mm× H 1600mm, 1500kg | ||||

Features

1. The sliding print head features a precise location and outstanding ink absorbency performance.

2. Equipped with an infrared locating system, the UV flatbed printer is capable of determining the exact position of the material.

3. Under normal usage, the LED lamps have a service life of 20,000 to 30,000 hours.

4. The crossbeam has a lifting height of 160mm with glass platform.

5. Using a wind cooling technology, the UV color printer requires no cooling fin, and significantly reduces losses caused by radiation.

Other advantages

1. Adjustable Ink Dot Size

This printer can utilize a Ricoh GH2220 print head with an ink dot size range of 3PL to 21PL, or an Epson print head with an ink dot size range of 3.5PL to 15PL. A smaller ink dot is recommended for precise patterns, a natural color transition and good structure, while a larger ink dot is better for intense colors and visual impacts.

2. Gorgeous Color

Making use of an advanced color adjustment system, our UV printers achieve a dot to dot printing process that can produce 4,096 grey level images. These printers are also capable of working with 68.6 billion colors, restoring faded natural colors to the best extent possible, as well as ensuring the highest consistency between the printing image and the original image.

3. White Ink Printing and 5D Printing Effect

In addition to the CMYK traditional 4 color ink system, the flatbed printing equipment is also capable of white ink printing. This means under printing on non-white media, and overprinting on transparent materials, as well as printing white as a spot color. When using 4 times the volume of white ink for printing, a 5D embossing effect is also achieved.

4. Sectional Vacuum System

The vacuum system is designed with an adjustable air flow, taking into consideration the tolerance of different materials. The entire system is flat, corrosion resistant and features a uniform vacuum force.

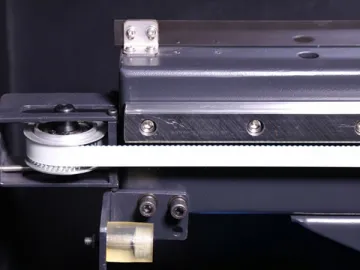

5. Large-Power Servo Motor

The X axis is equipped with an integrated servo motor, which allows for a high rotational speed, powerful force, a high speed, blockage free printing, and a long term performance. The Y axis is equipped with a synchronization system, which ensures an accurate synchronization of the left and right lead screws.

Links:https://globefindpro.com/products/52718.html

-

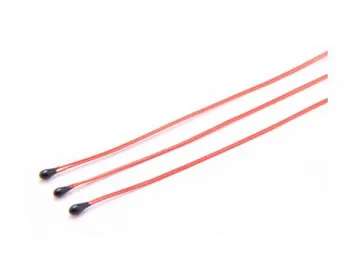

Thin Film NTC Thermistor, MJ/SP

Thin Film NTC Thermistor, MJ/SP

-

Temperature Sensor, Rivet Type, MJZP

Temperature Sensor, Rivet Type, MJZP

-

Filter Disc

Filter Disc

-

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh

-

PVC Coated Wire

PVC Coated Wire

-

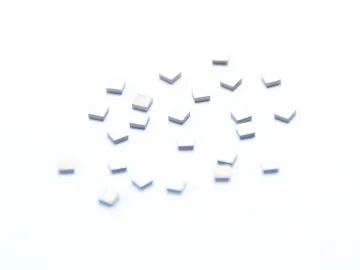

Leadless Chip NTC Thermistor, MJ/SL

Leadless Chip NTC Thermistor, MJ/SL

-

NTC Thermistor for Thermometer, MJ/SG

NTC Thermistor for Thermometer, MJ/SG

-

Radial Leaded Glass Encapsulated NTC Thermistor, MJ/SB

Radial Leaded Glass Encapsulated NTC Thermistor, MJ/SB

-

Temperature Sensor, Rivet Type, Waterproof Type, MJRC

Temperature Sensor, Rivet Type, Waterproof Type, MJRC

-

Temperature Sensor, Pot Bottom Type, MJRA

Temperature Sensor, Pot Bottom Type, MJRA

-

UV Flatbed Printer, WLD-UV2513

UV Flatbed Printer, WLD-UV2513

-

Thin-Film Temperature Sensor, Low Temperature Type, MJMB

Thin-Film Temperature Sensor, Low Temperature Type, MJMB