UV Flatbed Printer, WLD-UV2513

Designed to meet different requirements for high speed and extremely precise printing, the WLD-U2513 is a wide format UV flatbed printer, known in China for its outstanding performance. The use of 1200DPI (or 1440DPI) printing technology ensures a flawless performance, and is suitable for a wide range of printing requirements. The Epson print head also guarantees a consistent quality for all printing applications.

Applications

This UV printer is ideal for printing on acrylic, aluminum composite panels, wooden boards, ceramic tiles, foam boards, metal plates and paper.

Technical Parameters

| Print head | Epson DX7 | Ricoh GEN5 | Ricoh GH2220 | ||

| Number of print head | 1-2 | 3-8 | 4-16 | ||

| Ink dot size | 3.5PL | 7-35 PL | 3PL | ||

| Printing speed | Sketch mode | 36 m2/h | 72 m2/h | 48 m2/h | |

| Production mode | 24 m2/h | 48 m2/h | 28 m2/h | ||

| High quality mode | 14 m2/h | 32 m2/h | 14 m2/h | ||

| Media | Types | Acrylic, aluminum composite panels, wooden boards, ceramic tiles, foam boards, metal plates, paper, etc. | |||

| Thickness | 120mm | ||||

| Weight | 100KG | ||||

| Printing area | 2500mm×1300mm | ||||

| Ink types | Epson ink, 4 or 6 colors, white ink | Ricoh G5 ink, 4 or 6 colors, white ink, vanish | Ricoh GH2220 ink, 4 or 6 colors, white ink | ||

| Cleaning method | Siphon | Positive pressure | |||

| LED-UV lamps | Water cooling, UV lamps, 480W | Compressor cooling, UV lamps, 900W×2 | Water cooling, UV lamps 600W | ||

| Power supply | AC200V, main engine, 1000W LED-UV lamps, 480W Vacuum motor, 1500W | AC200V, main machine, 1000W LED-UV lamps, 1800W Vacuum motor, 1500W×2 | AC200V, main machine, 1000W LED-UV lamps, 1200W Vacuum motor, 1500W | ||

| Technical support | Protective cover | UV plate to isolate UV ray and protect eyes | |||

| Data interface | USB3.0 | ||||

| RIP software | PHOTOPRINT, MainTop, Recolor, color gate | ||||

| Image format | TIFF, JPEG, POSTSCRIPT3, EPS, PDF | ||||

| Color control | Compliant with ICC standard, with curve and density adjustment function | ||||

| Print head technology | drop ON DEMAND micro-pressure electric printing | ||||

| Printing mode | One-direction, dual-direction | ||||

| Working environment | Temperature: 20-28 ℃ Humidity: 40%-60% | ||||

| Printing resolution | 360×720 /720×720/1440×720 | 300×600/600×600/1200×1200 | |||

| Machine size | L 4020mm× W 2150mm× H 1260mm, 1250kg | ||||

| Packaging size | L 4250mm× W 2450mm× H 1600mm, 1400kg | ||||

Attractive Features

1. Ricoh Gen5 Industrial Print head

Imported from Japan, the industrial print head is extremely precise and features a minimum ink dot size of 7PL. It is capable of working continuously for 24 hours, at a printing speed of 15 square meters per hour. If working for a period of 10 hours every day, the service life reaches an average of 3 to 4 years. In addition, the Epson print head and Ricoh GH2220 print head are both available options.

2. Adjustable Ink Dot Size and Grayscale Technology

Making use of modern technology, the UV flatbed printer features an adjustable ink dot size and grayscale, meeting multiple industrial printing requirements. The small ink dot ensures exquisite patterns, a natural color transition and great structure. A larger ink dot ensures an intense color and visual impact.

3. Bright Colors

Utilizing an advanced color adjustment system, the WLD printer carries out a dot to dot printing process, and produces 4,096 grey level images. The printer is capable of working with 68.6 billion colors, restoring natural colors to as close to the original state as possible, and ensuring the consistency between the printed image and the original image.

4. White Ink Printing and 5D Printing Effect

In addition to printing with the traditional color ink system of CYMK, this flatbed printer also carries out white printing, which guarantees under printing on non-white media and overprinting on transparent materials, as well as printing white as a spot color. When using four times the volume of white ink for printing, the 5D embossing effect is achieved simultaneously.

5. Butt Welding Technology

The machine's strong frame is due to butt welding technology, and allows for a deformation capacity and strong body, even under extreme temperatures, rough transportation and usage stress.

6. Negative Pressure Control System

Using a 0.01PA high precision negative pressure control system, the print head carries out a smooth and even printing process, even at high speeds or after operating for long periods of time. In addition, the constant temperature system of the secondary ink cartridge guarantees a consistent color and printing quality, even in different environments and temperatures.

7. Sectional Vacuum System

The vacuum system features an adjustable air flow, taking into consideration different materials and their tolerance levels. The entire system is flat, corrosion resistant and features a uniform vacuum force.

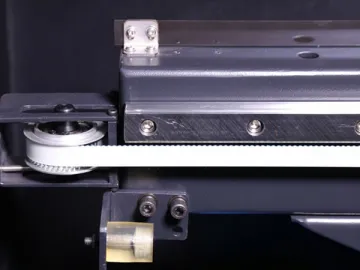

8. High-Power Servo Motor

Featuring a large torque, powerful force, precise, blockage free printing and a long service life, the XY axis is equipped with a high powered 400W AC servo motor. It is also equipped with a synchronization system, ensuring an accurate synchronization of the left and right lead screws.

9. High-Precision Locating

The high-precision lead screw ensures a precise location, as well as guaranteeing the ink is ejected into the correct location with no deviations.

10. User-Friendly Control Panel

The LCD control panel is equipped with a double-control system and features a high sensitivity. Users can even operate the system with gloves on.

11. Automatic Ink Circulation System

With the use of an anti-deposition circulation system, white ink continues to move in a set time cycle. In doing so, problems in print head blockages due to ink deposition are prevented.

12. LED-UV Energy-Saving Lamps

The flatbed printer uses an LED-UV energy saving lamp, featuring a long service life. Under normal operations, these environmentally friendly lamps work upwards of 25,000 hours, without flickering and generating no ozone. They are extremely secure and reliable.

13. Print Head Protection

As a piece of non-contact printing equipment, the print head comes installed with a bumper strip placed 5mm above it in order to avoid contact with uneven materials.

14. Temperature Control

The low-temperature LED curing light is paired with a water cooling system to prolong the lamp's service life and reduce malfunctions. The automatic heating system in the ink supply system also keeps the ink at a constant temperature. This allows the ink to remain in a liquid state, even in cold environments, thus ensuring a smooth ink supply and uniform color printing.

15. Frosted Treatment

The entire printing machine is frosted and designed with an arc outline to provide a professional appearance.

Links:https://globefindpro.com/products/52713.html

-

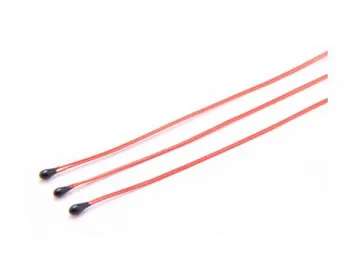

Temperature Sensor, Pot Bottom Type, MJRA

Temperature Sensor, Pot Bottom Type, MJRA

-

Temperature Sensor, Rivet Type, Waterproof Type, MJRC

Temperature Sensor, Rivet Type, Waterproof Type, MJRC

-

Radial Leaded Glass Encapsulated NTC Thermistor, MJ/SB

Radial Leaded Glass Encapsulated NTC Thermistor, MJ/SB

-

NTC Thermistor for Thermometer, MJ/SG

NTC Thermistor for Thermometer, MJ/SG

-

UV Flatbed Printer, WLD-UV4590

UV Flatbed Printer, WLD-UV4590

-

Thin Film NTC Thermistor, MJ/SP

Thin Film NTC Thermistor, MJ/SP

-

Thin-Film Temperature Sensor, Low Temperature Type, MJMB

Thin-Film Temperature Sensor, Low Temperature Type, MJMB

-

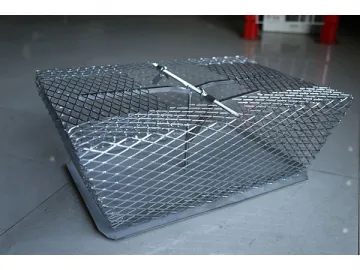

Spark Arrestor Chimney Cap

Spark Arrestor Chimney Cap

-

Fast-Response Thermistor Sensor, MJQ

Fast-Response Thermistor Sensor, MJQ

-

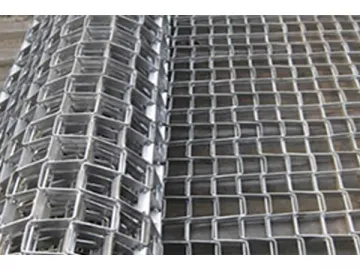

Conveyor Belt Wire Mesh

Conveyor Belt Wire Mesh

-

SMD MELF NTC Thermistor, MJ/ST

SMD MELF NTC Thermistor, MJ/ST

-

Perforated Tube

Perforated Tube