Toilet Roll Wrapper, TP-B30RE

Automatic Packaging Machine for Toilet Paper Roll (Bundle Pack)  20 packages/min Output 25kW Total power Length: 300-690 mm

20 packages/min Output 25kW Total power Length: 300-690 mm

Width: 160-440 mm

Height: 80-280 mm

Packaging dimension

Dimension of Individually Wrapped Tissue Packaging Style

Examples Specifications

Features Central vacuum supply is adopted for efficient reduction of power consumption; Intelligent heat sealing system, can accommodate various packaging materials while offering good sealing effect and high stability; Designed with various functions like automatic rejection of unopened bags, air source management, fault alarm and display, servo overload protection; Diagram Tags hand towel packing machine

tissue packaging machine

towel wrapper

film packaging machine

end-of-line packaging

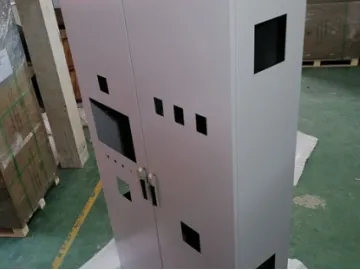

TP-B30RE toilet paper roll packaging machine is typically designed for automatic multi-packing of both core and coreless toilet paper rolls and kitchen tissue rolls. Servo drives are adopted to control operations including tissue roll arranging, counting, insertion rolls into bag and bag conveying, providing ease of operation and simple maintenance.

Width: 160-440 mm

Height: 80-280 mm

Packaging dimension

Dimension of Individually Wrapped Tissue Packaging Style

Examples Specifications

| Model | TP-B30RE |

| Application | Packaging of either core or coreless toilet paper rolls and kitchen tissue rolls |

| Dimension of individually wrapped tissue | Diameter: 80 mm-130 mm Height: 80mm-130 mm (error of single pack size ±2mm) |

| Feeding method | ASF automatic dual-lane/ three-lane feeding system |

| Design speed | 12-22 packages/min (depending on product size) |

| Working speed | 8-20 packages/min (depending on product size) |

| Package configuration (layer × row × column) | (1-3)×(2-3)× (4-6) |

| Tissue roll arrangement range | 80mm to 360mm |

| 160mm to 360mm | |

| 320mm to 690mm | |

| Gusset forming | Vacuum mold forming |

| Installation of packaging material | Bag racks mounted at both sides |

| Bag storage | ≤600 pre-made bags |

| Packaging material | PE, CPP film |

| Compressed air | Pressure 0.6MPa Air flow 300L/min |

| Power supply | 308V/50Hz |

| Total power | 19kW |

| Machine weight | 3400kg |

| Bag type | Pre-made bag |

| Servo control shafts | 10 shafts |

| System brands | Electrical control system: VEICHI, MITSUBISHI Temperature control system: YUDIAN Pneumatic system: SMC, AIRTAC |

| Optional | Ink roll coder, TTO printer |

tissue packaging machine

towel wrapper

film packaging machine

end-of-line packaging

Scan QR to Read

Links:https://globefindpro.com/products/5380.html

Links:https://globefindpro.com/products/5380.html

Recommended Products

Hot Products