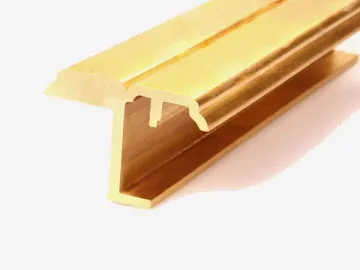

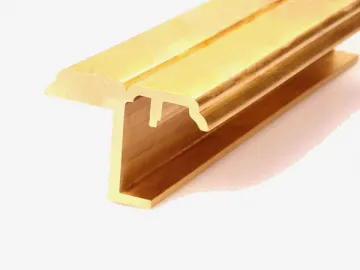

Extrusion Press (for Φ80mm Rod)

Brass Rod Extruder, Copper Extrusion Equipment, Rod Extrusion Press

The indirect extrusion machine is specially manufactured to produce copper rods. In indirect extrusion, the copper billet remains stationary while the die moves into the billet by the hollow raw, through which the backward extrusion take place.

Characteristics of Copper Extruder

1. There is no relative movement between billet and container, thus generating no friction or heat.

2. With this indirect extruder, 25%-30% extrusion force will be cut.

3. Profiles with smaller cross sectional area can be extruded by this copper rod machine at a lower temperature and a higher speed.

4. Uniform flow, small extrusion hole and low residual pressure contribute to stable mechanical properties of copper rods.

Technical Data of Copper Extrusion Equipment

| Model (Cu) | Rated pressure (MPa) | Size of standard copper billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-1630 | XJ-1800 | 21 | Φ178×770 | Φ80 | 80 | Φ186×120 | 1400 | 1000 |

| XJ-1800 | XJ-2000 | 21 | Φ178×820 | Φ80 | 80 | Φ186×120 | 1400 | 1000 |

Applications

Copper rods and copper alloy rods by this extrusion machine are widely used in generator, switch gear, transformer, to name a few.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53890.html

-

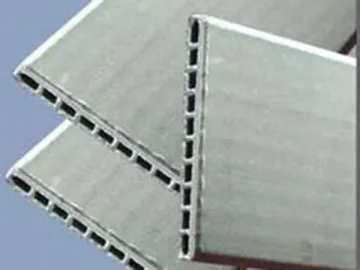

Extrusion Press (for Φ360mm Profile / Flat Bar)

Extrusion Press (for Φ360mm Profile / Flat Bar)

-

Extrusion Press (for Φ280mm Profile / Flat Bar)

Extrusion Press (for Φ280mm Profile / Flat Bar)

-

Extrusion Press (for Φ90mm Profile / Flat Bar)

Extrusion Press (for Φ90mm Profile / Flat Bar)

-

Extrusion Press (for Φ230mm Profile / Flat Bar)

Extrusion Press (for Φ230mm Profile / Flat Bar)

-

Extrusion Press (for Φ155mm Profile / Flat Bar)

Extrusion Press (for Φ155mm Profile / Flat Bar)

-

Double Action Extrusion Press for Φ170mm-Φ70mm Copper Seamless Tube

Double Action Extrusion Press for Φ170mm-Φ70mm Copper Seamless Tube

-

Extrusion Press (for Φ65mm Rod)

Extrusion Press (for Φ65mm Rod)

-

Downlead Clamp for ADSS

Downlead Clamp for ADSS

-

Batter Applicator

Batter Applicator

-

IQF Tunnel Freezer

IQF Tunnel Freezer

-

Oven Cooking Line

Oven Cooking Line

-

Peeler / Washer / Scrubber

Peeler / Washer / Scrubber