Extrusion Press (for Φ155mm Profile / Flat Bar)

Copper Extrusion Equipment, Brass Extrusion Machinery, Flat Bar Extruder

To satisfy the ever-changing customer demands, we developed and produced two types of extruders for φ155mm copper profile and flat bar: Long stroke back loaded copper extruder and short stroke front loaded copper extruder.

Major Features of Long Stroke Extrusion Machine

1. The machine can make use of unfixed dummy block, which saves money.

2. The diameter of extruded billets should be less than 152mm.

Major Features of Short Stroke Extrusion Machine

1. The machine uses unfixed dummy block for cost saving.

2. Short-length billets can be extruded by the short stroke machine.

3. Copper products processed by short stroke extruder have a strong structure and are not easy to deform.

4. In the manufacture process, the accuracy of guiding rail and the shaft center of extrusion can be ensured.

5. Short idle time.

Technical Information

| Model (Cu) | Rated pressure (MPa) | Size of standard copper billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-1250 | XJ-1400 | 21 | Φ152×620 | Φ125 | 125 | Φ300×300 | 1185 | 680 |

| XJ-1350 | XJ-1500 | 21 | Φ152×620 | Φ125 | 125 | Φ300×300 | 1185 | 680 |

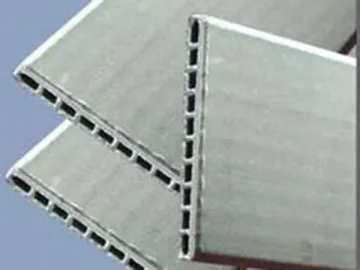

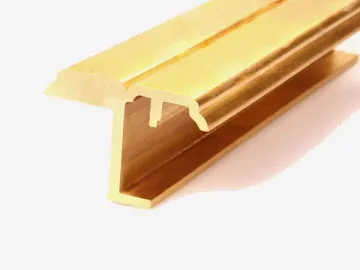

Applications

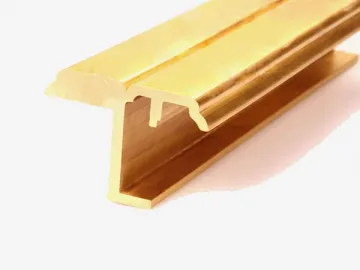

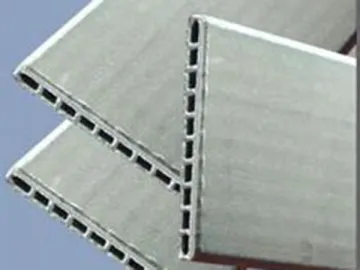

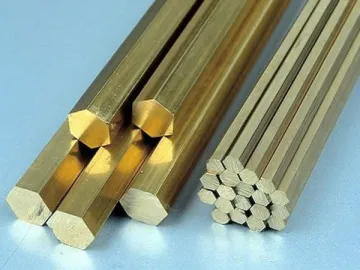

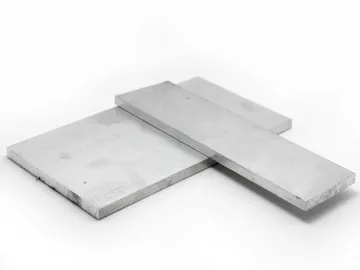

Appropriate to produce copper profiles, welding tubes, rods and flat bars.

Notes

Disadvantages of Long Stroke Extruder

1. Serious deformation under high pressure.

2. It's not easy to ensure the accuracy of guiding rail and the shaft center of extrusion.

3. Long idle time.

Disadvantages of Short Stroke Extruder

The short stroke extrusion equipment is not suited for billets with a diameter less than 152mm.

Links:https://globefindpro.com/products/53895.html

-

Double Action Extrusion Press for Φ170mm-Φ70mm Copper Seamless Tube

Double Action Extrusion Press for Φ170mm-Φ70mm Copper Seamless Tube

-

Extrusion Press (for Φ330mm Profile / Flat Bar)

Extrusion Press (for Φ330mm Profile / Flat Bar)

-

Extrusion Press (for Φ180mm Profile / Flat Bar)

Extrusion Press (for Φ180mm Profile / Flat Bar)

-

Extrusion Press (for Φ180mm Profile / Flat Bar)

Extrusion Press (for Φ180mm Profile / Flat Bar)

-

Extrusion Press (for Φ195mm Rod)

Extrusion Press (for Φ195mm Rod)

-

Extrusion Press (for Φ260mm Profile / Flat Bar)

Extrusion Press (for Φ260mm Profile / Flat Bar)

-

Extrusion Press (for Φ230mm Profile / Flat Bar)

Extrusion Press (for Φ230mm Profile / Flat Bar)

-

Extrusion Press (for Φ90mm Profile / Flat Bar)

Extrusion Press (for Φ90mm Profile / Flat Bar)

-

Extrusion Press (for Φ280mm Profile / Flat Bar)

Extrusion Press (for Φ280mm Profile / Flat Bar)

-

Extrusion Press (for Φ360mm Profile / Flat Bar)

Extrusion Press (for Φ360mm Profile / Flat Bar)

-

Extrusion Press (for Φ80mm Rod)

Extrusion Press (for Φ80mm Rod)

-

Extrusion Press (for Φ65mm Rod)

Extrusion Press (for Φ65mm Rod)