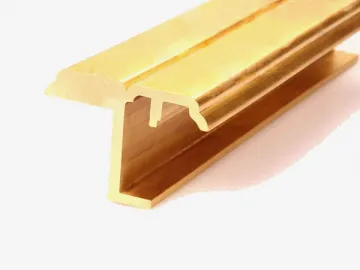

Extrusion Press (for Φ145mm Rod)

Copper Extrusion System, Rod Extruder, Brass Rod Extrusion Press

Differing from direct extrusion press, this indirect extrusion machine is especially designed. The die is mounted on the end of a hollow raw and moves into the billet by pushing forward the raw. Finally, well-extruded rods come out of the inner bore.

Benefits of Copper Extrusion System

1. With no relative movement between container and billet, there is no friction or heat while machine working.

2. 25%-30% less extrusion force is needed to complete the same extrusion work.

3. Metal billet with a small cross sectional area can be process with this rod extruder at a low temperature but high speed.

4. Uniform copper flow, small extrusion hole and low residual pressure all contribute to consistent and great mechanical performance.

Technical Parameters of Brass Rod Extrusion Press

| Model (Cu) | Rated pressure (MPa) | Size of standard copper billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-3600 | XJ-4000 | 25 | Φ279×1170 | Φ145 | 145 | Φ300×150 | 1800 | 2300 |

Applications

Copper rods extruded by this equipment are most often used as electronic components, solar energy tubes, transformer parts, to name a few.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53920.html

-

Double Action Extrusion Press for Φ70mm-Φ36mm Copper Seamless Tube

Double Action Extrusion Press for Φ70mm-Φ36mm Copper Seamless Tube

-

Double Action Extrusion Press (for Φ140mm-Φ65mm Tube)

Double Action Extrusion Press (for Φ140mm-Φ65mm Tube)

-

Double Action Extrusion Press for Φ160mm-Φ70mm Copper Seamless Tube

Double Action Extrusion Press for Φ160mm-Φ70mm Copper Seamless Tube

-

Double Action Extrusion Press for Φ200mm-Φ80mm Copper Seamless Tube

Double Action Extrusion Press for Φ200mm-Φ80mm Copper Seamless Tube

-

Extrusion Press (for Φ120mm Rod)

Extrusion Press (for Φ120mm Rod)

-

Double Action Extrusion Press for Φ170mm-Φ70mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ170mm-Φ70mm Aluminum Seamless Tube

-

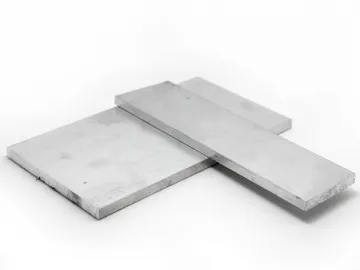

Extrusion Press (for Φ90mm Profile / Flat Bar)

Extrusion Press (for Φ90mm Profile / Flat Bar)

-

Extrusion Press (for Φ330mm Profile / Flat Bar)

Extrusion Press (for Φ330mm Profile / Flat Bar)

-

Extrusion Press (for Φ230mm Profile / Flat Bar)

Extrusion Press (for Φ230mm Profile / Flat Bar)

-

Extrusion Press (for Φ205mm Profile / Flat Bar)

Extrusion Press (for Φ205mm Profile / Flat Bar)

-

Extrusion Press (for Φ130mm Profile / Flat Bar)

Extrusion Press (for Φ130mm Profile / Flat Bar)

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)