LG-40

Our LG-40 hydraulic CFA piling rig is designed for several purposes. It is mainly used in the deep foundation projects of high rise building, high speed railway and high way with continuous flight augering technique.

The hydraulic piling rig can create various types of piles including HS piles, SDS piles and CFG piles, delivering fast piling speed, high pile quality, low noise, minimal vibration and no influence by underground water. It is suited to pile in multiple types of formations. This product obtained national invention patent in 2012.

Features

1. The piling rig is fully hydraulic driven, with electro-hydraulic proportional control. This ensures centralized operation, high safety and portability.

2. Main components including rotary table, main winch, track, undercarriage slewing unit, auxiliary winch, etc. are all equipped with balance valves, overload relief valves, brake and other devices for maximum safety.

3. Specially designed double drum winch (Patent No.: ZL 2010 1 0163348.4) makes sure the rotation head can realize full-stroke feeding with improving or reducing pressure. Feeding speed can be adjusted steplessly.

4. Large torque rotation head (Patent No.: ZL 2010 2 0179840.6) is uniquely designed to have two drive devices symmetrically placed, thus eliminating radial force on slewing bearing and effectively extending bearing life.

5. Sliding drill pipes (Patent No.: ZL 2010 2 0179884.9) are provided to transfer large rotary torque as well as double-direction axial force. The pipes can slide 5-8m to ensure an effective reduction of mast height and significant improvement of construction safety.

6. Hydraulic track system with continuously variable speed guarantees stable traveling and flexible turning. Hydraulic legs are used for leveling the piling rig, improving stability and safety and saving handling cost.

7. Placed in the front of the piling rig, operation cab provides broad vision. Equipped with a number of instruments and switches, it allows for real time supervision and control over the rig.

8. Mast and guide rail all feature rectangular box structure. They are fabricated from high strength structural steel, offering high robustness and aesthetically pleasing appearance.

Technical Parameters

| Model | LG-40 | |

| Drilling diameter | Φ400~600mm | |

| Drilling depth | 24 8 m | |

| Rotation head speed | 0~6r/min | |

| Rotation head output torque | 500 kN·m | |

| Rotation head travel | 24m | |

| Main winch hoisting capacity | 800 kN ( Double rope ) | |

| Main winch pressure capacity | 400 kN ( Double rope ) | |

| Auxiliary winch hoisting capacity | 50 kN ( Single rope ) | |

| Main pump power | 220kW | |

| Power of auxiliary pump 1 | 4 kW | |

| Power of auxiliary pump 2 | 37 kW | |

| System pressure | 28 MPa | |

| Traveling (track mounted) | Track gauge | 4800 mm |

| Track wheelbase | 5000 mm | |

| Track shoe width | 900 mm | |

| Gradeability | 5~25 ° | |

| Size (LxWxH) | Transportation size | 13600x3000x3400 mm |

| Working size | 12800x6770x28500 mm | |

| Total weight ( Working condition ) | 82t | |

Links:https://globefindpro.com/products/55168.html

-

PPS Needle Felt Filter Bag

PPS Needle Felt Filter Bag

-

TSJ300/400/600

TSJ300/400/600

-

Sulfide Stress Corrosion Cracking (SSC) Proof Ring System

Sulfide Stress Corrosion Cracking (SSC) Proof Ring System

-

Hip Seat

Hip Seat

-

Fiberglass Filter Cloth and Bag

Fiberglass Filter Cloth and Bag

-

Filter Cloth

Filter Cloth

-

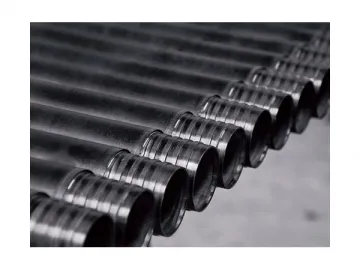

Drill Pipe (for Oil Industry)

Drill Pipe (for Oil Industry)

-

SPJC-400

SPJC-400

-

Coring Wrench / Full Circle Grip Wrench

Coring Wrench / Full Circle Grip Wrench

-

Trailer Mounted Hydraulic Core Drilling Rig XDJ-4

Trailer Mounted Hydraulic Core Drilling Rig XDJ-4

-

Casing Pipe

Casing Pipe

-

Drill Rod

Drill Rod