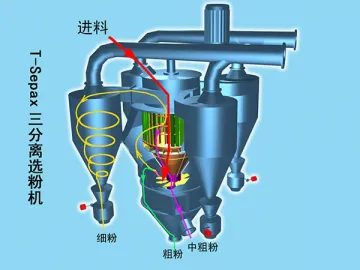

High Efficiency Cyclone Separator (for Powder)

Cyclonic separator is designed to eliminate particulates, such as dirt and dust, from a stream of air, gas or liquid. It features reasonable interior structure, high powder-selecting efficiency and energy efficiency. It is able to improve the capacity of the mill system. It has been extensively applied as an important classifying device in the closed-circuit raw grinding process in cement plants. It is also suitable for classification of other non-metal minerals in construction industry.

Technical Paramters

| Model | Targeted Fineness R0.08 (%) | Air Volume ( m³/h ) | Rotating Speed (r/min) | Main Motor Power (kw) | Maximum Feeding Amount (t/h) | Capacity (t/h) |

| KMS- Ⅰ | 0-3 | 16000 | 250-500 | 15.0 | 50 | 10-18 |

| KMS- Ⅱ | 0-3 | 23000 | 220-450 | 18.5 | 90 | 16-28 |

| KMS- Ⅲ | 0-3 | 32000 | 180-400 | 22.0 | 120 | 2040 |

| KMS- Ⅳ | 0-3 | 45000 | 160-340 | 30.0 | 150 | 30-50 |

| KMS- Ⅴ | 0-3 | 60000 | 130-306 | 30.0 | 210 | 40-70 |

| KMS- Ⅵ | 0-3 | 75000 | 130-260 | 37.0 | 260 | 50-85 |

| KMS- Ⅶ | 0-3 | 95000 | 120-240 | 45.0 | 330 | 75-110 |

| KMS- Ⅷ | 0-3 | 120000 | 110-200 | 55/75 | 400 | 95-130 |

| KMS- Ⅸ | 0-3 | 150000 | 110-180 | 90/110 | 500 | 110-160 |

| KMS- Ⅹ | 0-3 | 180000 | 110-170 | 110/132 | 580 | 120-180 |

Scan QR to Read

Links:https://globefindpro.com/products/55540.html

Links:https://globefindpro.com/products/55540.html

Recommended Products

-

Dry Magnetic Separator

Dry Magnetic Separator

-

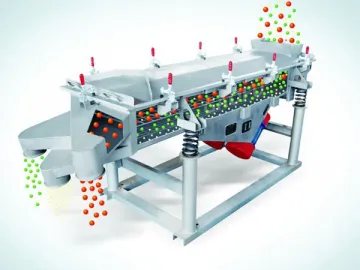

High Frequency Screen

High Frequency Screen

-

Hematite Separation Line

Hematite Separation Line

-

Plate and Frame Filter Press

Plate and Frame Filter Press

-

Linear Vibrating Screen

Linear Vibrating Screen

-

Intermittent Ball Mill

Intermittent Ball Mill

-

Air Swept Ball Mill

Air Swept Ball Mill

-

Gold Gravity Separation Line

Gold Gravity Separation Line

-

Cement Cyclone Preheater

Cement Cyclone Preheater

-

Magnetite Magnetic Separation Line

Magnetite Magnetic Separation Line

-

HGMS Electromagnetic Separator

HGMS Electromagnetic Separator

-

Sand Washing Machine

Sand Washing Machine