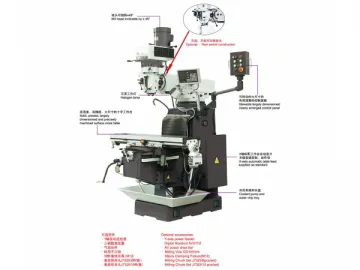

Variable Speed Milling Machine

VariableSpeed Milling Machine

,

±45° Mill head inclinable by ±45°

Halogen lamp

、、 Solid, precise,largely dimensioned and precisely machined surface cross table

: Optional: Ram swivel construction

Slewable largely dimensioned clearly arrangedcontrol panel

X 、 X-axis automatic table feed supplied asstandard

Coolant pump and water chip tray

Optional accessories

Y Y-axis power feeder

Digital Readout for X/Y/Z

Air power draw bar

Milling vice QG100mm

58(M12) 58pcs Clamping fixture(M12)

J7325(8/) Milling chuck set J7325 (8pcs/set)

J7325(15/)Milling chuck set J7325(15pcs/set)

This variable speed milling machine can executelots of machining process, from easy to complex, such as slot and keywaycutting, planing, drilling, contouring, and diesinking, also the processing precision is very high. Thecutting fluid is usually pumped to the cutting site to cool down and lubricatethe cut and wash away the residue. This equipment is the same as “OPTIMUM” milling machine of Germany, andit can be supplied at an affordable price.

Technical Parameters

| Model | TM500 |

| Code | 5015003 |

| Capacity | |

| Max. Drilling Capacity | 24mm |

| Max. Milling Capacity of Cutter Head | 100mm |

| Max. Milling Capacity of End Mill Cutter | 20mm |

| Spindle Holding Fixture | |

| Spindle Taper | NT40 |

| Sleeve Diameter | 100mm |

| Sleeve Travel | 127mm |

| Drill Mill Head | |

| Head Incline (L-R) | 90° |

| Head Incline (back-forth) | 0° |

| Speed | |

| Spindle Speed | 50-3750rpm |

| Cross Table | |

| Table Size (L×W) | 250×1270mm |

| X-axis Automatic Travel | 800mm |

| Y-axis Manual Travel | 360mm |

| Z-axis Travel | 420mm |

| Size/Distance/Number of T-slot | 16mm/64mm/3 |

| Max. Spindle-Cross Table Distance | 500mm |

| Spindle-Machine Body Distance Range | 130-645mm |

| Electricity Supply | |

| Motor | 3.75kW/3ph/50Hz/380V |

| Motor Coolant Pump | 40W |

| Dimension and Weight | |

| Size | 2750×2030×2340mm |

| Net/Gross Weight | 1650/1850kg |

Features

1. The heavy solid structure of our variable speed milling machine is realized by high-grademechanical casting.

2. Solid rectangular slide way is designed for Z-axis and all axes are set with adjustable dovetail slide ways.

3. Automatic spindle sleeve feeding is available.

4. Two rotation modes which are right and left handed exist in this equipment.

5. High precision of concentricity is achieved because of the taper roller bearings,and less than 0.01mm is measured in the spindle sleeve.

6. This milling machine has main switch with motor protection, right/lefthanded rotation switch, and emergency stop button.

Links:https://globefindpro.com/products/56039.html

-

7-inch Headrest Car DVD Player

7-inch Headrest Car DVD Player

-

Tire Balancer

Tire Balancer

-

Adobe Photoshop CS6

Adobe Photoshop CS6

-

JPS-12DBP Fuel Injection Pump Test Bench

JPS-12DBP Fuel Injection Pump Test Bench

-

JCRS Common Rail Test Bench

JCRS Common Rail Test Bench

-

MQ-550 Exhaust Gas Analyzer

MQ-550 Exhaust Gas Analyzer

-

Potassium Acetate Snow / Ice Thaw Agent

Potassium Acetate Snow / Ice Thaw Agent

-

Ultrasonic Cleaning Machine

Ultrasonic Cleaning Machine

-

Auto Lift

Auto Lift

-

MQY-200 Smoker Meters / Opacimeters

MQY-200 Smoker Meters / Opacimeters

-

Hydraulic Press

Hydraulic Press

-

Adobe Dreamweaver CS3

Adobe Dreamweaver CS3