Impact Crusher

Under the drive of electromotor, impact crusher's rotor is ina high speed rotation. Materials are impacted and crushed with the hammer on therotor when they are getting in. Then these materials are been crashed again whenthey are beat back on the scale board. At last, the materials are dischargedfrom the discharge mouth. Impact crusher has efficient energy-saving, uniquestructure and counterattack scale board. Its products are in cubic shape. Theparticle size can be adjusted and the crushing processes can be simplified.Impact crusher can be widely used in water and electricity, highway, artificialaggregate, crushing and other industries.

Features of ImpactCrusher:

| Model | Size of rotor (mm) | Feed opening (mm) | Max. feed size (mm) | Handling capacity (t/h) | Power of motor (kW) | Weight (t) |

| IC107 | Φ1000×700 | 400×730 | 300 | 15-30 | 37 | 6 |

| IC101 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 75 | 12.5 |

| IC121 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 16.5 |

| IC124 | Φ1250×1400 | 400×1430 | 350 | 90-180 | 132 | 19 |

| IC135 | Φ1320×1500 | 860×1520 | 500 | 120-250 | 200 | 24 |

| IC120 | Φ1320×2000 | 860×2030 | 500 | 160-350 | 260 | 27 |

Links:https://globefindpro.com/products/57998.html

-

Webcam, WRT-T52

Webcam, WRT-T52

-

ABH3000 Hot Mix Asphalt Plant

ABH3000 Hot Mix Asphalt Plant

-

Pipelayer YFP-8

Pipelayer YFP-8

-

Vibrating Screen

Vibrating Screen

-

Air-Cooled Diesel Engine DAC-2

Air-Cooled Diesel Engine DAC-2

-

Mixer Truck (10m3)

Mixer Truck (10m3)

-

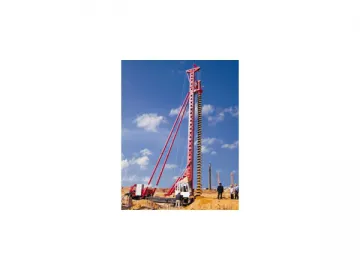

Caterpillar Type Drilling Machine

Caterpillar Type Drilling Machine

-

Air-Cooled Diesel Engine DAC-1

Air-Cooled Diesel Engine DAC-1

-

Special Engine Repair Tools

Special Engine Repair Tools

-

AH5323GJB Mixer Truck

AH5323GJB Mixer Truck

-

MODU150 Concrete Batch Plant

MODU150 Concrete Batch Plant

-

MODU120 Concrete Batch Plant

MODU120 Concrete Batch Plant