Closed Circuit Cooling Tower

Principle and Application

The closed circuit cooling tower consists of a module with a red copper coil with high heat transfer system efficiency. It is designed for purified water or other cooling liquids to pass through its pipeline and collect heat in the system while exchanging that thermal energy with the air. It is suitable for long-term operation by connecting the water inlet and outlet at the installation site. The cooling tower is designed to work with induction heating equipment, IF furnaces and die casting machines.

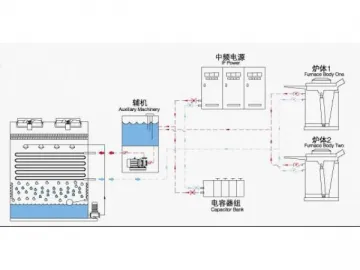

Water Circuit Drawing Of Closed Cooling Tower

Performance and Features:

1. Light weight and small footprint available for free relocation, automatic digital display of temperature, energy efficient and environmentally friendly, easy installation, operation and maintenance

2. Available for direct use requiring no pool, pump and piping, etc. to saving the need for huge and complex water cooling facilities and saving workshop space.

3. Enclosed soft water circulating cooling to prevent piping blockages caused by sundries protecting electric components against scale so as to decrease the fault rate of IF, HF and other heating equipment.

Applications

1. Induction heating furnace and diathermic furnace

2. High and medium frequency melting furnaces, IGBT induction quenching furnace

3. Rolling mill, die-casting machine, injection molding machine

※ The amount of fluid required for cooling fluid varies according to the different power levels and cooling equipment. Our technicians will calculate the amount of cooling fluid for you.

Links:https://globefindpro.com/products/58585.html