Governor Ropes

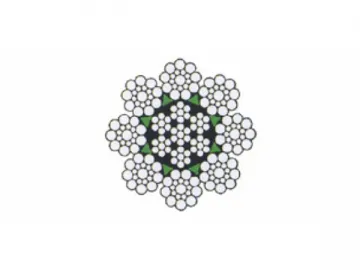

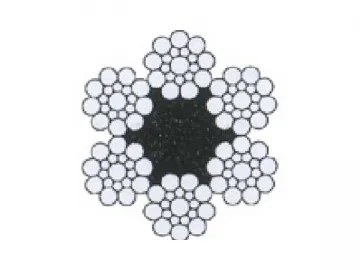

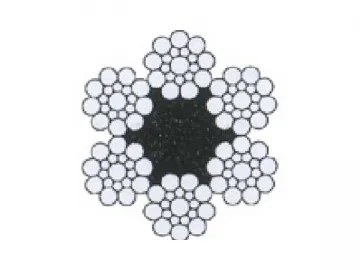

Governor ropes are indispensable elevator parts. They are connected to the elevator car to maximize running safety. Junwei wire ropes in 6-strand×19 wires, 6-strand×24 wires and 6-strand×25 wires are ideal for governor ropes for elevators. They deliver unbeatably high strength, wear resistance and long service life.

Specifications of the Elevator Wire Rope6×S(19) 6×W(19) 6×Fi(25)

| 6×S(19) | 6×W(19) | 6×Fi(25) | ||||

| Construction | Fiber Core 6× ( 1 9 9 ) | Construction | Fiber Core 6× { 1 6 ( 6 6)} | Construction | Fiber Core 6× { 1 6 ( 6) 12 } | |

| Lay of wire rope | Ordinary lay: Z or S Lang's lay: Z or S | |||||

| Nominal diameter of rope (mm) | Calculated sectional area (mm2) | Breaking load (KN) | Approx. weight per meter (kg/m) | |||

| Bright Galvanized | ||||||

| Grade E | Grade A | Grade B | Special Grade | |||

| 4 | 6.7 | - | - | 9.29 | 9.77 | 0.062 |

| 5 | 10.3 | - | - | 14.5 | 15.3 | 0.096 |

| 6 | 14.8 | 16.1 | 19.6 | 20.9 | 22 | 0.139 |

| 6.3 | 16.3 | 17.7 | 21.6 | 23 | 24.2 | 0.153 |

| 8 | 26.2 | 28.6 | 34.9 | 37.2 | 39.1 | 0.247 |

| 9 | 33.2 | 36.2 | 44.1 | 47 | 49.5 | 0.312 |

| 10 | 41 | 44.7 | 54.5 | 58.1 | 61.1 | 0.386 |

| 11.2 | 51.4 | 56.1 | 68.3 | 72.8 | 76.6 | 0.484 |

| 12 | 59 | 64.4 | 78.5 | 83.7 | 88 | 0.556 |

| 12.5 | 64.1 | 69.9 | 85.1 | 90.7 | 95.4 | 0.603 |

| 14 | 80.4 | 87.7 | 107 | 114 | 120 | 0.756 |

| 16 | 105 | 115 | 139 | 149 | 156 | 0.988 |

| 18 | 133 | 145 | 176 | 188 | 198 | 1.25 |

| 20 | 164 | 179 | 218 | 232 | 244 | 1.54 |

Note:

1. The table is only for reference purposes without guarantee or warranty as to its accuracy. Real data may vary slightly due to test methods and environmental influence.

2. In addition to industrial standards such as EN and JIS standards, Junwei wire ropes can be manufactured to your individual specifications. Contact us for details.

6×24

Governor Ropes:

| 6×24 | ||||||

| Construction | 6×(a 9 15) | |||||

| Lay of wire rope | Ordinary lay: Z or S Lang's lay: Z or S | |||||

| Nominal diameter of rope (mm) | Calculated sectional area (mm2) | Breaking load (KN) | Approx. weight per meter (kg/m) | |||

| Galvanized | Bright | |||||

| Grade G | Grade A | |||||

| 6 | 12.5 | 16.5 | 17.7 | 0.12 | ||

| 8 | 22.2 | 29.3 | 31.6 | 0.212 | ||

| 9 | 28.1 | 37.1 | 39.9 | 0.269 | ||

| 10 | 34.8 | 45.8 | 49.3 | 0.332 | ||

| 12 | 50 | 65.9 | 71 | 0.478 | ||

| 14 | 68.1 | 89.7 | 96.6 | 0.651 | ||

| 16 | 89 | 117 | 126 | 0.85 | ||

| 18 | 113 | 148 | 160 | 1.08 | ||

| 20 | 139 | 183 | 197 | 1.33 | ||

| 22 | 168 | 222 | 239 | 1.61 | ||

| 24 | 200 | 264 | 284 | 1.91 | ||

| 26 | 235 | 309 | 333 | 2.24 | ||

| 28 | 272 | 359 | 387 | 2.6 | ||

| 30 | 313 | 412 | 444 | 2.99 | ||

Note:

1. The table is only for reference purposes without guarantee or warranty as to its accuracy. Real data may vary slightly due to test methods and environmental influence.

2. In addition to industrial standards such as EN and JIS standards, Junwei wire ropes can be manufactured to your individual specifications. Contact us for details.

Links:https://globefindpro.com/products/59059.html