Compressor Industry

Typical parts of an air conditioning compressor that can be machined using PCBN cutting tools include flanges, cylinders, and crankshafts. The material is a gray cast iron. The service life of our PCBN cutting tools are 5-10 times longer than coated carbide tools, and are 1-3 times as efficient.

Common Funik PCBN cutting insertsFBS7000 WNGA080408 S02020

FBN7000 WNGN080408 S02020

Flange

Cylinder

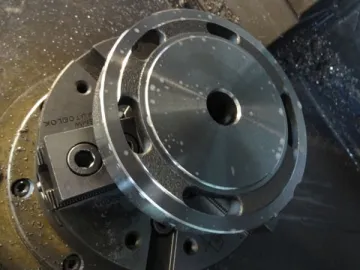

Customer CaseWork piece: air conditioning compressor flange

Material: HT250 HT200

Hardness: HB160-230

Processing methods: wet cutting

Original cutting tool: coated tools

Current cutting tool: Funik's FBS7000 WNGA080412

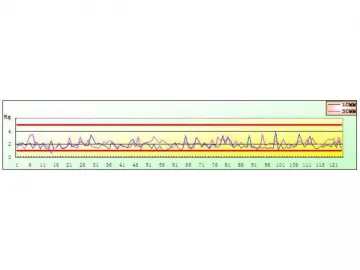

Efficiency comparison: increased from 58 seconds/piece to 37 seconds/piece, efficiency 1:3

Life comparison: increase from 20 pieces/edge to 80 pieces/edge, 3 times life upgrade

About the Customer

The customer is a refrigeration equipment manufacturer based in Guangzhou. Due to the serious discontinuity of flange processing, the cutting tool was damaged quickly by the impact. The coated carbide tool requires frequent replacement, which results in a rising cost. In addition, the replacement of cutting tools takes time and lowers production efficiency. PCBN cutting inserts from other companies ended up chipped or broken.

Customer Feedback

Since we started using Funik's PCBN cutting inserts, we have only needed to replace the inserts once per shift. It works 4-6 times longer than that of cutting tools from other suppliers. The speed is also increased from 800 r/minute, to 1200 r/minute., and the production efficiency has been increased by more than 50%.

Links:https://globefindpro.com/products/59337.html