Welding Robot SA1800

SA series robots are compact, small and lightweight, ideal for welding application due to its high stability to finish welding job. It can realize high welding-path accuracy, considerably reduce welding cycle-time, and extend the lifetime of tubes and cables. In addition, SA Series robots can fit in narrow working space and can be floor mounted, inverted or wall mounted at any angle.

Robot SA1800 has 8kg wrist payload and 1818mm maximum working radius.

Features

1.Large working space

2.Lightweight

3.High running speed

4.High position repeat accuracy

5.Good welding reliability

Main Applications

Arc Welding, Cutting

1. Stability improves welding quality which ensures uniformity

2. Improve productivity and 24 hours’ continuous production

3. Improve labor’s working condition, long term operation in harmful condition

4. Reduce requirements for operation technique

5. Shorten the period of remodel change, reduce the relevant equipment cost

6. Realize bulk article of welding automation

7. Save floor space

Material Handling, Palletizing

1. More flexible, more stable, less energy consumption

2. High performance of moving stuff

3. Exceptionally long run time

4. Fixed automation

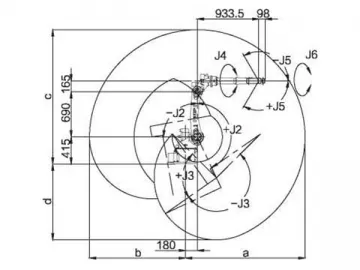

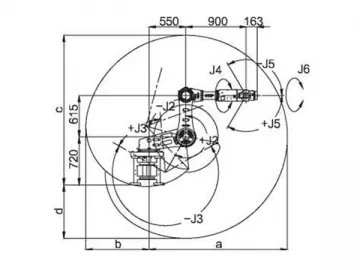

| a | 1818 |

| b | 1458 |

| c | 2053 |

| d | 1158 |

Technical Specifications

| Model | SA1800 | |

| Wrist Payload | 8 kg | |

| Max Working Radius | 1818 mm | |

| DOF | 6 | |

| Max Speed | J1 | 150° /s |

| J2 | 150° /s | |

| J3 | 160°/s | |

| J4 | 360°/s | |

| J5 | 320°/s | |

| J6 | 360°/s | |

| Max Operation Area | J1 | ±165° |

| J2 | 155°〜90° | |

| J3 | 80o-190° | |

| J4 | ±185° | |

| J5 | ±120° | |

| J6 | ±360° | |

| The Max Moment Allowable Torque | J5 | 54 Nm |

| J6 | 29 Nm | |

| Weight | 160 kg | |

| Position Repeat Accuracy | ± 0.05 mm | |

| Working Temperature | 0-40°C | |

Links:https://globefindpro.com/products/5952.html

-

PG series Inline Booster Pump

PG series Inline Booster Pump

-

WZB series Peripheral Pump

WZB series Peripheral Pump

-

Diesel Engine for Water Pump (1, 3, 4, 6 Cylinders)

Diesel Engine for Water Pump (1, 3, 4, 6 Cylinders)

-

XBD series Electric Fire Pump

XBD series Electric Fire Pump

-

QDX series Submersible Sewage Pump (Thread Port)

QDX series Submersible Sewage Pump (Thread Port)

-

WQ series Submersible Sewage Pump

WQ series Submersible Sewage Pump

-

Bending Robot SR50B

Bending Robot SR50B

-

Frequency Inverter (Cabinet Type), AS700 Series

Frequency Inverter (Cabinet Type), AS700 Series

-

Wire Mesh Belt & Cotton Belt

Wire Mesh Belt & Cotton Belt

-

Bread / Cake Double Deck Switchover Cooling Conveyor

Bread / Cake Double Deck Switchover Cooling Conveyor

-

Rotary Template Depositor

Rotary Template Depositor

-

Automatic Tin Loading System For Cookies

Automatic Tin Loading System For Cookies