Servo System for Bag Making Machine

Abstract

This article analyzes the workings of the bag making machine, further introduces the use of F series servo system on the heat sealer and cutter, and gives readers several key parameter settings of the servo drive.

Foreword

The number of industrial uses for the bag making machine is nearly endless, as it is commonly seen in handbags, luggage, shoes and hats, synthetic rubber, ropes, strips, and coils industries. Other popular applications include:

1. Leather, paper, conductive fabrics, foam, acetate cloth

2. PET, electrical insulation paper, rubber gasket

3. Fabric tape, hook and loop fastener, safety belt, color strip,

4. PVC sponge, copper foil, aluminum foil, flexible printed circuit

Gives you a general idea of what a bag making machine looks like.

| Operator interface | stand-alone microcontroller | servo drive | servo motor | |||

| servo drive signal | ||||||

| temperature control signal | temperature controller | knife temperature | ||||

| color lines (on the bags) signal | main variable frequency drive | VFD motor | ||||

| high position (of knife holder) signal | alarm control |

1. Acceleration

2. Constant speed

3. Deceleration

4. Low-speed searching for color lines (on the bags)

5. Bag length

6. Next bag making cycle

Wiring

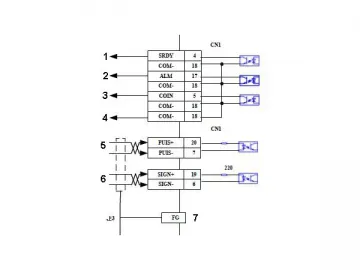

The servo drive can be directly connected across the mains power grid. The wiring for the standalone microcontroller and servo drive is shown in fig. 4.

Fig. 4

1. Servo enable

2. Alarm clearance

3. Clockwise drive restricted

4. Counter-clockwise drive restricted

5. Pulse prohibited

6. Servo ready

7. Servo alarm

8. Motor braking output

9. DG output common port

The table below lists several key parameter settings of the servo system.

| PA-1 | 44 | Motor code |

| PA-5 | 80 | Proportional gain in a velocity loop |

| PA-9 | 60 | Proportional gain in a positional loop |

| PA-12 | 30 | Gear ratio numerator |

| PA-13 | 4 | Gear ratio denominator |

| PA-15 | 1 | Selection of servo arm orientation |

| PA-32 | 1 | Speed estimation mode |

| PA-33 | 215 | Load inertia setting |

Please note:

The speed of servo system response increases by more than 30% if the servo is set on the speed estimation mode PA-32=1. This increase only occurs when the load inertia is properly set.

Links:https://globefindpro.com/products/60196.html

-

Gas Delivery and Material Handling

Gas Delivery and Material Handling

-

Forced Draft

Forced Draft

-

Variable Frequency Drive (Inverter Drive, AC Drive)

Variable Frequency Drive (Inverter Drive, AC Drive)

-

VFD for Industrial Washing Machine

VFD for Industrial Washing Machine

-

American Type Trailer Axle

American Type Trailer Axle

-

Other Trailer Parts

Other Trailer Parts

-

Milestone

Milestone

-

Servo System for PCB Drilling and Milling Machine

Servo System for PCB Drilling and Milling Machine

-

Servo System for Six-axis Articulated Robot

Servo System for Six-axis Articulated Robot

-

Inverter Drive to Achieve Power Balance on Belt Conveyor

Inverter Drive to Achieve Power Balance on Belt Conveyor

-

Metallic Glass Mosaic

Metallic Glass Mosaic

-

Duffel Bags

Duffel Bags