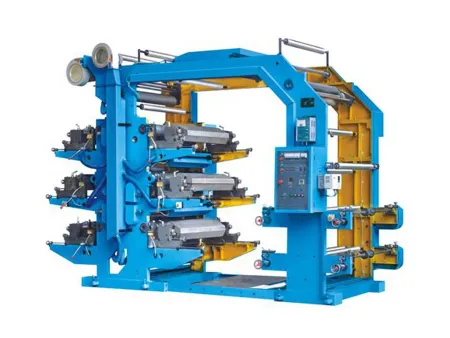

2 Color Flexographic Printing Machine

CI Flexo Press for Film & Paper Printing  Technical Parameters

Technical Parameters

Main part

Unwinder & Rewinder 1. Single unwinder & rewinder

2. 5kg automatic tension brake

3. Tension sensor (optional)

4. Auto tension controller (optional)

5. Air shaft: 76mm (optional)

6. EPC motor (optional)

7. EPC sensor (optional)

Printing System 1. Doctor blade (optional)

2. Anilox roller

3. Separate motor for ink roller.

4. Adjust bar, hard screw

5. Ink pump (optional)

6. Oil lubrication system

7. Hydraulic lifting system (optional)

Transfer System 1. Synchronous belt

2. Extremely robust helical gear

3. NSK bearing

Drying System 1. Separate drying heaters

2. Up drying system

This 2 color flexographic printing machine uses sensitization resin in its printing plate for high flexibility, making it ideal for many packaging materials, including polyethylene, polypropylene bags, cellophane and paper roll. This flexo printing machine is perfect for making plastic and paper food bags, supermarket bags, vest bags, and clothing bags, among other items.

| Model | YT-2600 | YT-2800 | YT-21000 | YT-21200 |

| Max. effective printing width (mm) | 560 | 760 | 960 | 1160 |

| Max. web width (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing speed (m.min) | 60 | 60 | 60 | 60 |

| Max. mechanical speed (m/min) | 70 | 70 | 70 | 70 |

| Max. diameter of roll material (mm) | 450 | 450 | 450 | 450 |

| Roll material inner diameter (mm) | 76 | 76 | 76 | 76 |

| Repeated length (mm) | 191-1200 | 191-1200 | 191-1200 | 191-1200 |

| Accuracy (mm) | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Power of heater (kW) | 4 | 6 | 8 | 10 |

| Total power (kW) | 8 | 10 | 12 | 12 |

| Weight (kg) | 1800 | 200 | 2200 | 2400 |

| Dimensions(mm) | 2.5*1.7*2.2 | 2.5*1.9*2.2 | 2.5*2.1*2.2 | 2.5*2.3*2.2 |

Unwinder & Rewinder 1. Single unwinder & rewinder

2. 5kg automatic tension brake

3. Tension sensor (optional)

4. Auto tension controller (optional)

5. Air shaft: 76mm (optional)

6. EPC motor (optional)

7. EPC sensor (optional)

Printing System 1. Doctor blade (optional)

2. Anilox roller

3. Separate motor for ink roller.

4. Adjust bar, hard screw

5. Ink pump (optional)

6. Oil lubrication system

7. Hydraulic lifting system (optional)

Transfer System 1. Synchronous belt

2. Extremely robust helical gear

3. NSK bearing

Drying System 1. Separate drying heaters

2. Up drying system

Scan QR to Read

Links:https://globefindpro.com/products/602.html

Links:https://globefindpro.com/products/602.html

Recommended Products

-

Single-layer Blown Film Machine

Single-layer Blown Film Machine

-

High Speed 4/6 Color Flexographic Printing Machine

High Speed 4/6 Color Flexographic Printing Machine

-

Hydraulic Punch Press

Hydraulic Punch Press

-

Three Layer Blown Film Machine

Three Layer Blown Film Machine

-

Mini Type Blown Film Machine

Mini Type Blown Film Machine

-

Garment Bag Making Machine

Garment Bag Making Machine

-

6 Color CI Flexo Printing Machine

6 Color CI Flexo Printing Machine

-

Three Layer Blown Film Machine

Three Layer Blown Film Machine

-

PP Blown Film Machine

PP Blown Film Machine

-

4/6 Color Flexographic Printing Machine

4/6 Color Flexographic Printing Machine

-

High Speed Flexo Printing Machine

High Speed Flexo Printing Machine

-

High Speed Blown Film Machine with Double Rewinder

High Speed Blown Film Machine with Double Rewinder

Hot Products