Environmental Protection

Our company attaches great importance to social responsibility. We have introduced various techniques to reduce the pollution.

We adopt abrasive blasting technique to replace the traditional technique for the surface treatment. During the process, small steel balls will be ejected to the surface of the safe to remove the contaminations and enhance the roughness, so that the paint can adhere to the surface tight for a long time.

However, the traditional surface treating technique, acid washing, means that components will be washed in acid washing pool to remove the rust from the surface, but the surface will not be roughened. Thus the adhesiveness between the paint and surface will not be high enough, leading to the gradually falling off of the paint. The acid solution can get into the safe through some tiny gaps at the welding parts and is difficult to be dried. After the painting, it could come out and rust the body. Additionally, the acid is very corrosive, so the introduction of abrasive blasting technique in 2011 also has contributed a lot to the environmental protection.

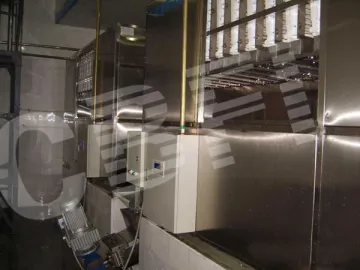

The painting process is conducted by a painting line, so the productivity is quite amazing. The painting residue and powder caused by the grinding process will be collected by a specific device through the vacuuming system. Thus the worker health and environment are both well protected.

Links:https://globefindpro.com/products/60771.html

-

MB80 Ice Block Machine Sold to Burkina Faso

MB80 Ice Block Machine Sold to Burkina Faso

-

Heavy Duty Wheel Balancer

Heavy Duty Wheel Balancer

-

Railway Station and Airport

Railway Station and Airport

-

Ice Block Machine Supplied to Beijing Olympic Games

Ice Block Machine Supplied to Beijing Olympic Games

-

CV5000 Cube Ice Machine Exported to Syria

CV5000 Cube Ice Machine Exported to Syria

-

2 Post Lift

2 Post Lift

-

Orbital Pipe Cutting & Beveling Machine

Orbital Pipe Cutting & Beveling Machine

-

Test Equipment

Test Equipment

-

Our Vision

Our Vision

-

Stone Working Tool and Concrete Tool

Stone Working Tool and Concrete Tool

-

Intelligent LED Light

Intelligent LED Light

-

Manufacture Facility

Manufacture Facility