Furniture Board

Artificial boards like the particle board, fiberboard and the melamine board are commonly used for furniture manufacturing. It is important to use the appropriate board material. Next, we'd like to introduce several kinds of board frequently applied to furniture fabrication.

Melamine Board

The melamine board is a kind of man-made board finished with melamine impregnated paper. To get this decorative board, we should first put the paper of different colors and textures into the melamine resin adhesive for soaking. Then the paper should be dried and solidified to a certain degree. Next, it is used as the surface of the particle board, MDF or the hard fiberboard, and finally hot pressing can be performed. Generally, several pieces of paper can be used together during that process and the paper amount depends on actual conditions.

The melamine board has the advantages like smooth surface, bright color, low price, no deformation, high resistance to abrasion and corrosion, etc. The quality of melamine board made in Lu Shuihe is relatively good on the domestic market, and relevant indicators are also in compliance with international standards.

Fire-Proof Board

The fire-proof board is a kind of decorative board. Generally, siliceous or calcareous materials are mixed with fiber materials, lightweight aggregates, adhesives and chemical additives in certain proportion, and then this board is obtained through high-pressure steaming technique. Specifically, it is composed of surface paper, colored paper and multi-layer kraft paper. Its thickness is 0.6-1.2mm.

The fire-proof board is hardwearing, high-temperature resistant, anti-scratch, permeation resistant and easy to clean. It is divided into many types, such as the metal type, matte coated type, etc. You can apply it to kitchen cabinet, showcase or other special environments. As a combination of beauty and practicability, it occupies a dominant position on the market.

Besides, the requirement for adhesive is relatively high during the application of fire-proof board, and also gluing thickness and time as well as high skill are very important.

Particle Board

There are wide varieties of particle board, such as the wood grain type, straw type, wheat-straw type, sugarcane type, etc. The particle board for furniture is also named as flake board. To get this kind of artificial board, we should first cut wood residue, undersized log or wood shaving into pieces. Then, drying and mixing with adhesive, hardener and waterproof agent under certain temperature and pressure should be performed.

The particle board has good sound insulating effect, uniform composition, stable performance, high strength, ageing resistance, smooth surface and small thickness error. It is fit for paint coating and the other finishing. Yet, due to rough edge and moisture absorption, corresponding edge banding measures should be taken to avoid deformation. Besides, as it may contain free formaldehyde, it is inferior to wood in screw fastening.

Density Fiberboard

The density fiberboard mainly covers the medium density fiberboard (MDF) and the high density fiberboard (HDF), the thicknesses of which are respectively are 450-800kg/m3 and >800kg/m3. It can be made from various kinds of materials, among which the wood fiber is commonly used. Generally, a series of fabrication procedures like defibering, surface coating, hot pressing and molding are required.

Links:https://globefindpro.com/products/61340.html

-

Motor Scooter

Motor Scooter

-

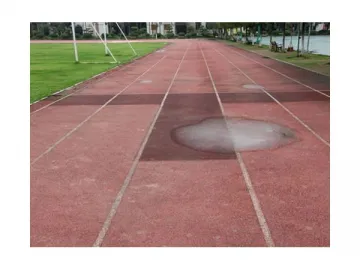

Better Physical Performance of the Prefabricated Track Surface

Better Physical Performance of the Prefabricated Track Surface

-

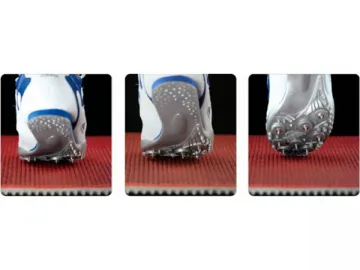

Superiorities of Tongxin Prefabricated Track Surfaces

Superiorities of Tongxin Prefabricated Track Surfaces

-

R&D Ability

R&D Ability

-

Highways

Highways

-

TSV Series Twin Screw Extrusion Equipment

TSV Series Twin Screw Extrusion Equipment

-

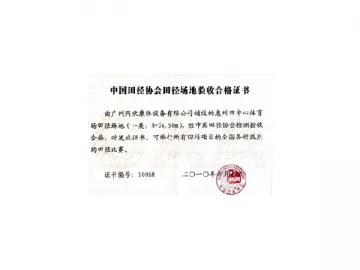

Worry-free Support in Site Acceptance

Worry-free Support in Site Acceptance

-

Rich and Optimized Product Lines

Rich and Optimized Product Lines

-

Rotary Tablet Press

Rotary Tablet Press

-

Win-Win System

Win-Win System

-

T8 LED Tube

T8 LED Tube

-

Professional and Experienced Construction Team

Professional and Experienced Construction Team