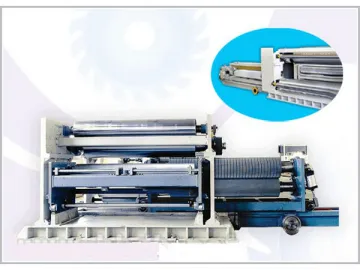

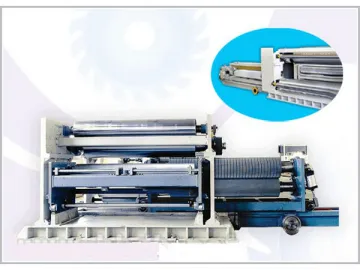

Corrugated Board Twin Facer

Corrugated Board Twin Facer

Features

1. Our double facer adopts a vacuum suction system to ensure a good flute form. It is designed with a double-flute structure. One flute forming unit forms the paperboard into a fluted pattern while the other unit applies pre-heating to the paper. Thanks to the clutch, the flute size can be easily and conveniently changed.

2. The glue application unit of the corrugated paper twin facer comes with a block design, a variable frequency drive, straight-line guide way, and hydraulic lock. It can achieve pneumatic control of the movement of the glue trough and electric control of glue application. Details on glue coating are displayed on the screen of the digital read out.

3. Automatic glue circulation and feeding system is used to avoid deposition of the glue.

4. The twin facer is also equipped with a spraying device.

5. Its corrugating roll is made of 48CrMo alloy steel through grinding and induction hardening to achieve a harness of HRC56-60.

6. The variable frequency drive motor transmission facilitates acceleration and deceleration of the machine.

7. Operational stability is attained as a result of two individual-drive units, gimbal transmission, isolated dynamic vibration, and flood lubrication.

8. The upper corrugating roll and gluing roll are hydraulically controlled.

9. The bearings of corrugating rolls and pressure rolls are lubricated with high temperature resistant lubricating grease. Manually operated centralized lubricating system is also available.

Specifications

1. Design speed: 250m/min

2. Corrugating roll diameter: 320mm

3. Available width: 1600mm-2200mm

4. Heat source: steam

Features

1. Our double facer adopts a vacuum suction system to ensure a good flute form. It is designed with a double-flute structure. One flute forming unit forms the paperboard into a fluted pattern while the other unit applies pre-heating to the paper. Thanks to the clutch, the flute size can be easily and conveniently changed.

2. The glue application unit of the corrugated paper twin facer comes with a block design, a variable frequency drive, straight-line guide way, and hydraulic lock. It can achieve pneumatic control of the movement of the glue trough and electric control of glue application. Details on glue coating are displayed on the screen of the digital read out.

3. Automatic glue circulation and feeding system is used to avoid deposition of the glue.

4. The twin facer is also equipped with a spraying device.

5. Its corrugating roll is made of 48CrMo alloy steel through grinding and induction hardening to achieve a harness of HRC56-60.

6. The variable frequency drive motor transmission facilitates acceleration and deceleration of the machine.

7. Operational stability is attained as a result of two individual-drive units, gimbal transmission, isolated dynamic vibration, and flood lubrication.

8. The upper corrugating roll and gluing roll are hydraulically controlled.

9. The bearings of corrugating rolls and pressure rolls are lubricated with high temperature resistant lubricating grease. Manually operated centralized lubricating system is also available.

Specifications

1. Design speed: 250m/min

2. Corrugating roll diameter: 320mm

3. Available width: 1600mm-2200mm

4. Heat source: steam

Related Names

Double Face Cardboard Producing | Corrugated Fiberboard Making Equipment

Scan QR to Read

Links:https://globefindpro.com/products/63820.html

Links:https://globefindpro.com/products/63820.html

Recommended Products

-

Carton Creasing and Cutting Machine

Carton Creasing and Cutting Machine

-

GS-Chitosanase

GS-Chitosanase

-

Helical Knives NC Cutting Machine

Helical Knives NC Cutting Machine

-

Automatic Box Gluer Machine

Automatic Box Gluer Machine

-

High Speed Carton Flexo Printer Slotter Die Cutter

High Speed Carton Flexo Printer Slotter Die Cutter

-

Paperboard Gluing Machine

Paperboard Gluing Machine

-

Chitosan Capsule / Tablet

Chitosan Capsule / Tablet

-

Multiple Corrugated Cardboard Preheater

Multiple Corrugated Cardboard Preheater

-

Computerized Cardboard Slitter Scorer

Computerized Cardboard Slitter Scorer

-

NC Thin Blade Slitter Scorer

NC Thin Blade Slitter Scorer

-

Corrugated Cardboard Hydraulic Mill Roll Stand

Corrugated Cardboard Hydraulic Mill Roll Stand

-

Semi Automatic Gluer Machine

Semi Automatic Gluer Machine