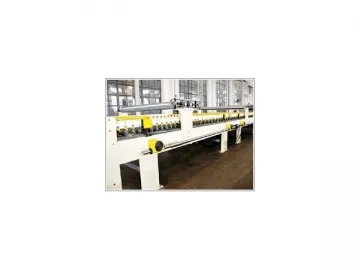

Water Ink Multi Color Cardboard Box Printer Slotter Die Cutter

Water Ink Multi Color Cardboard Box Printer Slotter Die Cutter

Paper Feeding Unit

1. The paper feeding unit of our water ink multi color cardboard box printer slotter die cutter adopts the chain drive to push the paperboard into the machine for further processing.

2. Opening and closing of the unit adopts the electrical traveling and pneumatic locking system. The feeder also can provide overloading protection function.

3. The upper axle of the paper feeding roller adopts the embossing feeding roller while the lower axle uses the steel embossing roller. The surface of these two rollers is put through hard chrome plating treatment to ensure smooth feeding without damaging the corrugated surface of the paperboard.

4. The printing roller of printer slotter die cutter comes with an optional economical printing plate with slots. Plate assembly and disassembly is independently controlled by the foot switch. The angle of the printing roller can be adjusted in 360 degree by the electrical numeric control system. Error correction is done by inputting correction data into the numeric control system for automatic modulation.

Ink Circulation System

1. The anilox roller is made of 200 or 220 pieces of steel wires.

2. The rubber roller adopts the natural rubber as its making material. The rubber is oil-proof, acid and alkali resistant.

3. The inking system adopts the pneumatic diaphragm pump in achieving automatic ink circulation. The pump can accomplish automatic cleaning by adding water into the system.

4. The cleaning-free ink circulation system gives a good printing quality and is able to maintain a consistent inking speed thus ensuring an even ink distribution over the paperboard.

5. The anilox roller and the rubber roller adopt the pneumatic control. The fast lowering and rising movement of the system ensures a clear and vivid printing of small-sized letters, elaborate patterns and overlapping colors.

Slotting Unit (optional)

1. The phase position of the slotting unit can be electrically adjusted in 360 degree.

2. The height of the box is manually adjusted. The four knives can achieve synchronization in slotting.

3. The upper and lower knife plate, the upper and lower creasing device, paper trimming knife, and creasing shaft as well as scale and pointer of the SYK4260 or SYK4860 slotting unit can be moved as a whole to another position. The printing width and length adjustment becomes easier.

4. The slotting unit adopts the pneumatic joint control system. It has the function of counting and alarming.

Technical Parameters

Model | Work Efficiency (pieces/minute) | Effective Printing Area(mm2) | Paper-feeding Area (mm2) | Thickness of plate(mm) | Width of the slot(mm) |

SYK4260-1800 | 0-60 | 1800×1270 | 2000×1270 | 6 | 7 |

SYK4260-2000 | 0-60 | 2000×1270 | 2200×1270 | 6 | 7 |

SYK4260-2200 | 0-60 | 2200×1270 | 2400×1270 | 6 | 7 |

SYK4260-2400 | 0-60 | 2400×1270 | 2600×1270 | 6 | 7 |

SYK4860-N | 0-60 | N×1470 | (N 200)×1470 | 6 | 7 |

SYK5260-N | 0-60 | N×1600 | (N 200)×1600 | 6 | 7 |

SYK6050-N | 0-60 | N×1800 | (N 200)×1800 | 6 | 7 |

SYK7150-N | 0-60 | N×2200 | (N 200)×2200 | 6 | 7 |

Related Names

Wide Printing Area Printer | Printer Slotter with Four Knife Die Cutter | Carton Printing and Making Device | Packing Machine

Links:https://globefindpro.com/products/63833.html

-

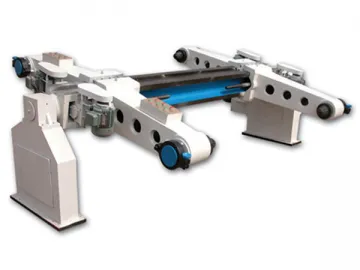

Rotary Die Cardboard Cutting Machine

Rotary Die Cardboard Cutting Machine

-

Corrugated Cardboard Baker

Corrugated Cardboard Baker

-

Single Face Corrugated Board Making Machine

Single Face Corrugated Board Making Machine

-

Automatic Carton Cutter and Creaser

Automatic Carton Cutter and Creaser

-

Mechanical Paperboard Cut Off Machine

Mechanical Paperboard Cut Off Machine

-

Automatic Crash Lock Carton Folder Gluer Machine

Automatic Crash Lock Carton Folder Gluer Machine

-

High Purity Chitin

High Purity Chitin

-

Automatic Flute Laminating Machine

Automatic Flute Laminating Machine

-

Rotary Cardboard Cut Off Machine

Rotary Cardboard Cut Off Machine

-

Rotary Cardboard Slotting Machine

Rotary Cardboard Slotting Machine

-

Chitosan Soap

Chitosan Soap

-

D-Glucosamine Hydrochloride/Sulfate Capsule and Tablet

D-Glucosamine Hydrochloride/Sulfate Capsule and Tablet