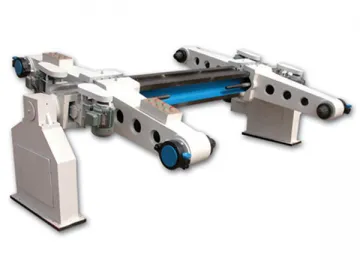

Single Face Corrugated Board Making Machine

Single Face Corrugated Board Making Machine

The single face corrugated board making machine consists of the mill roll stand, single face corrugated board forming device, and rotary cutting device. It is a semi-automatic production line, using paper roll as making material to produce and cut single face corrugated board according to the required specifications. The output paperboard no longer needs extra drying. This series of corrugated board making machine can be used in combination with the gluing machine or laminator to produce 3 plies or even more plies corrugated paperboard. It features optimized production process, high production efficiency, low labor intensity requirement, and simple operation. It is suitable for bulk production of good quality paperboards and is the ideal equipment for the medium- and small-size carton manufacturers who seek technical innovations.

Technical Parameters

Model | Working Speed (m/min) | Flute Type | Heating Method |

DWJ-1400 | 30-80 | (U/V)A B C E F | Electricity, Steam, Liquefied Gas, Conduction Oil |

DWJ-1600 | 30-80 | (U/V)A B C E F | Electricity, Steam, Liquefied Gas, Conduction Oil |

DWJ-1800 | 30-80 | (U/V)A B C E F | Electricity, Steam, Liquefied Gas, Conduction Oil |

Related Names

One Side Corrugated Cardboard Production Line | Equipment to Produce One-Sided Corrugated Fiberboard | Molding and Cutting Machine | High Efficiency Corrugated Sheet Producing

Links:https://globefindpro.com/products/63836.html

-

Automatic Carton Cutter and Creaser

Automatic Carton Cutter and Creaser

-

Mechanical Paperboard Cut Off Machine

Mechanical Paperboard Cut Off Machine

-

Automatic Crash Lock Carton Folder Gluer Machine

Automatic Crash Lock Carton Folder Gluer Machine

-

Mill Roll Stand for Corrugated Cardboard

Mill Roll Stand for Corrugated Cardboard

-

D-Glucosamine Sulfate 2NaCl

D-Glucosamine Sulfate 2NaCl

-

Chitosan Nitrate

Chitosan Nitrate

-

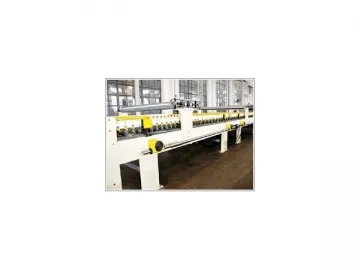

Corrugated Cardboard Baker

Corrugated Cardboard Baker

-

Rotary Die Cardboard Cutting Machine

Rotary Die Cardboard Cutting Machine

-

Water Ink Multi Color Cardboard Box Printer Slotter Die Cutter

Water Ink Multi Color Cardboard Box Printer Slotter Die Cutter

-

High Purity Chitin

High Purity Chitin

-

Automatic Flute Laminating Machine

Automatic Flute Laminating Machine

-

Rotary Cardboard Cut Off Machine

Rotary Cardboard Cut Off Machine