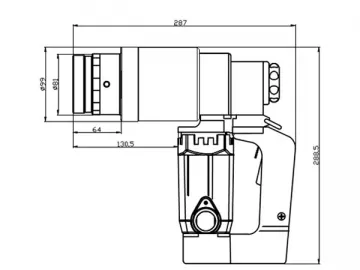

Longitudinal Seam Welding Machine

Longitudinal Seam Welding Machine

Longitudinal seam welding machine can work with argon arc welding machine, gas shielded arc welding machine, and plasma power to complete the longitudinal seam welding process of sheet or thin-walled cylinder. When it works with TIG, it can finish TIG welding operations for stainless steel sheet and ordinary steel sheet. One-side welding with back formation is also available. This product is the essential and indispensable machine for many industries, such as pressure vessel, chemical equipment, aerospace device, locomotive and vehicle, metallurgy, food machinery and household appliance, etc. In addition, loose package is adopted, and the electrical control box is set in the plywood case.

Technical Parameters

ZH Longitudinal Seam Welding Machine | ||||||

Model | ZH-500 | ZH-1000 | ZH-1500 | ZH-2000 | ZH-3000 | ZH-3500 |

Workpiece Length (mm) | ≤500 | ≤1000 | ≤1500 | ≤2000 | ≤3000 | ≤3500 |

Min. Cylinder Diameter (mm) | Φ110 | Φ150 | Φ180 | Φ230 | Φ340 | Φ400 |

Workpiece Thickness (mm) | 0.2-6 | 0.4-6 | 0.8-8 | |||

Welding Speed (mm/min) | 150-1500 | |||||

Speed Control | FC stepless speed | |||||

Workpiece Clamp Method | Pneumatic | |||||

Travelling Precision of Welding Gun (mm) | ±0.1 | ±0.15 | ±0.2 | |||

Usage and Maintenance

Proper usage and frequent maintenance are very important to guarantee the good performance and long service life of this seam welding machine.

1. Make sure that the devices that supply power, gas and water are in good condition.

2. Our machine has many functions, but any improper operation will lead to the abnormal working. So, please read this guide book carefully before use, and don’t attempt to execute the operations that not mentioned in this book.

3. After the workpiece is loaded, you must rotate the handle of mandrel locking mechanism to locking position, otherwise, the mandrel distortion phenomenon will occur.

4. The foot switch is self-locking, and you need to pay attention to the force exerted, because the shake of foot switch will influence the pressuring process of air bag.

5. All the fasteners should be checked regularly, because the equipment may be damaged if it works with loose component.

Our longitudinal seam welding machine is a high quality and efficient welding device for longitudinal seams, and deformation is avoided. This product is suitable for carbon steel, low alloy steel, stainless steel, aluminum, aluminum alloy and other materials. It adopts cantilever structure which facilitates the loading and unloading operations of workpiece, and the two cantilevers are annealed to eliminate the stress after they are welded. So, the cantilevers can keep steady without deformation for a long time. Also, precise guide rail is applied to guarantee the stable travelling of trolley. This equipment adopts DC motor drive method which is efficient and energy saving, and it allows easy control and convenient maintenance as well. Pneumatic clamp mode is used, and the seam is uniformly compacted within the welding length.

Links:https://globefindpro.com/products/64192.html

-

GD518 Combustible Gas Detector

GD518 Combustible Gas Detector

-

Hepatitis A (Live) Vaccine, Freeze-dried

Hepatitis A (Live) Vaccine, Freeze-dried

-

Combustible Gas Detector

Combustible Gas Detector

-

CO747 Carbon Monoxide Detector

CO747 Carbon Monoxide Detector

-

Photoelectric Smoke Detector

Photoelectric Smoke Detector

-

Rabies Vaccine (Hamster Kidney Cell) for Human Use

Rabies Vaccine (Hamster Kidney Cell) for Human Use

-

Hydraulic Pressing Machine

Hydraulic Pressing Machine

-

Small Printing Machine

Small Printing Machine

-

Electric Shear Wrench SAV-30E

Electric Shear Wrench SAV-30E

-

Electric Torque Wrench T-5

Electric Torque Wrench T-5

-

Custom Metal Sign Board

Custom Metal Sign Board

-

CNC Flame & Plasma Cutting Machine

CNC Flame & Plasma Cutting Machine