CNC Flame & Plasma Cutting Machine

CNC Flame & Plasma Cutting Machine

CNC flame and plasma cutting machine is a high efficiency and high precision cutting machine with many functions. It is used to cut longitudinal multipoint slat, crosswise slat, and geometrical graph at any plane. The frame type structure ensures great intensity and rigidity. Meanwhile, Panasonic automatic digital AC servo drive system is introduced from Japan, and Neugart large ratio planetary reducer is imported from Germany. Based on these, our cutting machine allows great cutting precision as well as steady running. In addition, loose package is adopted, and the electrical control cabinet is in the plywood case.

Technical Parameters

Model | CNC-CG-3000 | CNC-CG-4000 | CNC-CG-5000 | CNC-CG-6000 |

Rail Span (mm) | 3000 | 4000 | 5000 | 6000 |

Rail Length (mm) | 15000 | |||

Effective Cutting Length (mm) | 12500 | |||

Effective Cutting Width (mm) | 2200 | 3200 | 4200 | 5200 |

Cutting Speed (mm/min) | 20-4000 | |||

Quantity of Strip Cutting Torch | 9 | |||

Quantity of CNC Cutting Torch | 2 | |||

Cutting Thickness (mm) | 6-150 | |||

Maintenance

1. Please clean the CNC flame and plasma cutting machine regularly, such as dust removal of the CNC box, electrical elements in the power box and others.

2. The gear, gear case, rack and rail should be cleaned and filled with lubricating oil periodically.

3. Dismount and wash the dust catcher regularly.

This CNC flame and plasma cutting machine provides different working modes, and it is suitable for cutting stainless steel, nonferrous metal plate with small and medium thickness. Also, it can be used to cut carbon steel plate with the same quality. Meanwhile, our product has a human-computer interface which allows easy operation, and convenient installation is also realized which can save the installation and test time greatly. The rail length is 15000mm while the effective cutting length is 12500mm. Moreover, the cutting speed range is 20-4000mm/min, which means that fast cutting and high working efficiency is achieved. In addition, the well designed structure of our product guarantees the precision and balance during working, and the service life is extended.

Links:https://globefindpro.com/products/64186.html

-

Custom Metal Sign Board

Custom Metal Sign Board

-

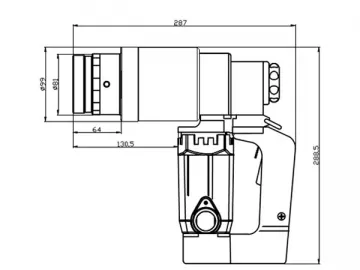

Electric Torque Wrench T-5

Electric Torque Wrench T-5

-

Electric Shear Wrench SAV-30E

Electric Shear Wrench SAV-30E

-

Small Printing Machine

Small Printing Machine

-

Hydraulic Pressing Machine

Hydraulic Pressing Machine

-

Longitudinal Seam Welding Machine

Longitudinal Seam Welding Machine

-

Electric Torque Wrench NLL-12TE

Electric Torque Wrench NLL-12TE

-

Custom European Size License Plate

Custom European Size License Plate

-

Reflective Film

Reflective Film

-

Milling and Chamfering Machine

Milling and Chamfering Machine

-

Sticker

Sticker

-

Custom Traffic Sign Plate

Custom Traffic Sign Plate