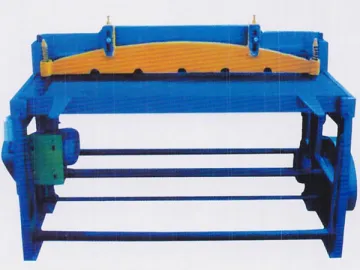

Hydraulic Shearing Machine / Sheet Metal Folder

Here at Guoxin, as a prominent roll forming line manufacturer, we offer an outstandinghydraulic shearing machine to improve your sheet metal shearing productivity. The hydraulic shear comes with an upper blade which carries out a reciprocating rectilinear motion against the fixed lower blade to cut metal plates. Relying on the clearance between the upper and lower blades, the sheet metal shear can be used to cut sheet metals of thicknesses up to 20mm.

Additionally, our 2-6m hydraulic shearing machine can also serve as a small sheet metal folder without the need of a power supply. It is suitable for bending the sheet metal used to make profiles for electrical switch cabinets, file cabinets, and kitchen utensils. The sheet folding machine can be used to bend carbon steel plate, stainless steel plate, aluminum plate, and copper plate among others.

We can design and build a variety of hydraulic shearing machines to meet your needs. Please do not hesitate to contact us if you are interested.

Main Parameters of Hydraulic Shearing Machine

| Max. sheet metal thickness | 20 mm |

| Max. sheet metal width | 2500 mm |

| Sheet metal tensile strength | 450 N/mm2 |

| Shear angle | 0.5°~3° |

| Shearing times | 6-20 n/min |

| Max. back gauge range | 1000 mm |

| Blade length | 2600 mm |

| Main motor power | 30 Kw |

| Gear pump | 63 L/min |

| Blade material | 9CrSi |

| Number of CNC axle | 3 axles |

| X axle--- control back gauge's front and back movement and position it X1 axle--- control back gauge pneumatic blanking S axle --- control shear angle | |

| Max. back gauge traveling speed | 300 mm /S |

| Repeated positioning accuracy of back gauge | 0.02 mm |

| Straightness accuracy | 0.3/m |

| Dimension (L×W×H) | 3260mm × 1900 mm × 2510mm |

Working Environment

| Power supply | 3P, 380V, 50Hz |

| Installation space | Clean, less dust |

| Max. air temperature | 40℃ |

| Min. air temperature | -5℃ |

| Relative humidity | 55~85% |

| Altitude | <1000M |

Product Showcase

Links:https://globefindpro.com/products/70317.html

-

Bending Machine

Bending Machine

-

Conventional Pipe Welding Rotator

Conventional Pipe Welding Rotator

-

Strand Jack

Strand Jack

-

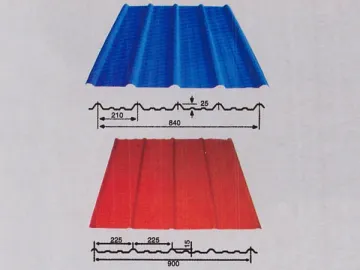

Roll Forming Machine (for Roof Panel and Wall Panel)

Roll Forming Machine (for Roof Panel and Wall Panel)

-

Self Aligning Pipe Welding Rotator

Self Aligning Pipe Welding Rotator

-

Chamfering Machine

Chamfering Machine

-

Automatic Pipe Welding Turning Roll

Automatic Pipe Welding Turning Roll

-

Roll Forming Machine (for Glazed Tile)

Roll Forming Machine (for Glazed Tile)

-

Jacking Control System

Jacking Control System

-

90° Steel Overturning Machine

90° Steel Overturning Machine

-

Steel Overturning Machine

Steel Overturning Machine

-

CNC Flame Cutting Machine

CNC Flame Cutting Machine