Concrete Block Making Machine, QT4-15

Technical Parameters of QT4-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500times/sub | ||||

| Total weight | 6200kg | ||||

| Overall Dimension | 9450×3300×2700mm | ||||

| Installed capacity | 20kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 25Mpa | ||||

| Exciting force | 68kN | ||||

| Plate specification | 980×560×20mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture | |||||

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 300×150×60 |

| Molding blocks | 4pcs/mold | 26pcs/mold | 14pcs/mold | 16pcs/mold | 9pcs/mold |

| Molding cycle | 15~20s | 20~30 s | |||

| Per hour production | 720pcs/1h | 4680pcs/1h | 2520pcs/1h | 2880pcs/1h | 1620pcs/1h |

| Class production | 5760- 7680pcs/8h | 37400- 49920pcs/8h | 20160- 26880pcs/8h | 20000- 25000pcs/8h | 12600- 13000pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 20kW | ||||

| Machine size | 9450×3300×2700mm | ||||

| Machine weight | 6200kg | ||||

**Note: The above parameters are for reference only. Modifications or upgrades are available. Please contact us directly for more information.

The QT4-15 concrete block making machine is a concrete block production equipment with a compact structure. Its semi-automatic control system allows the equipment to operate easily and its affordable pricing helps reduce production costs.

Application

This concrete block making machine is ideally suited for different construction materials such as concrete blocks, solid, hollow or cellular blocks, paving stones with or without a face mix, garden and landscaping products, slabs, edgers, curbstones, grass bricks, slope blocks, interlocking blocks and more. The raw materials for the semi-automatic concrete block equipment includes crushed stone, sand, cement, lime, fly ash, cinder, slag, gangue, gravel, perlite and other industrial waste. This machine is used for making hollow bricks, solid bricks, porous bricks or pavement bricks commonly used in the construction of buildings, roads, gardens and more.

Maintenance

Proper maintenance extends the service life of the concrete block making machine and ensures its correct operation.

1. When using the multi-purpose block making machine, as long as conditions allow, let the machine operate automatically, reducing the frequency of lever usage.

2. If manual operation is essential, pull the levers or turn the rotary knob gently. Keep the operation box clean and do not put anything inside. This prevents damage to the operation screen.

3. As you adjust the concrete block machine using the touch screen, keep your hand clean and touch the screen gently with the pads of your fingers, rather than fingernails.

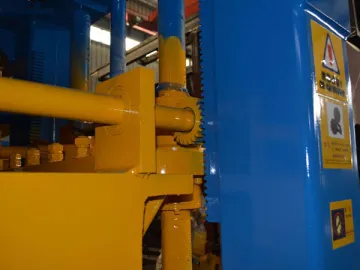

Pictures of Details

Detail of the main machine body

Gear Material feeding system

Spring of vibrating table

For more molds and samples, please click ""

Links:https://globefindpro.com/products/70482.html

-

Stainless Steel Fittings

Stainless Steel Fittings

-

Center Line Butterfly Valve

Center Line Butterfly Valve

-

Concrete Block Making Machine, QT10-15

Concrete Block Making Machine, QT10-15

-

Dry Barrel Fire Hydrant

Dry Barrel Fire Hydrant

-

Multifunctional Fluid Bed Granulator / Pelletizer / Coater

Multifunctional Fluid Bed Granulator / Pelletizer / Coater

-

Concrete Block Making Machine, QT9-15

Concrete Block Making Machine, QT9-15

-

Stainless Steel Ball Valve

Stainless Steel Ball Valve

-

Valve Accessories

Valve Accessories

-

Fire Protection Gate Valve

Fire Protection Gate Valve

-

Industrial Grinder for Fiber Grinding

Industrial Grinder for Fiber Grinding

-

Flanged Ball Valve

Flanged Ball Valve

-

Post Indicator

Post Indicator