Concrete Block Making Machine, QT10-15

Technical Parameters of QT10-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500times/sub | ||||

| Total weight | 13800kg | ||||

| Overall dimension | 1150×4050×2800mm | ||||

| Installed capacity | 45.2kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 31.5Mpa | ||||

| Exciting force | 105kN | ||||

| Plate specification | 1100×880×25mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3.0kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture | |||||

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60 | 250×250×60 |

| Molding blocks | 10pcs/mold | 51pcs/mold | 24pcs/mold | 36pcs/mold | 10pcs/mold |

| Molding cycle | 15~20 s | 20~30s | |||

| Per hour production | 1800pcs/1h | 9180pcs/1h | 4320pcs/1h | 6480pcs/1h | 1800pcs/1h |

| Class production | 14400- 19200pcs/8h | 74880- 99840pcs/8h | 34560- 46080pcs/8h | 51840pcs/8h | 14400pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 45.2kW | ||||

| Machine size | 11500×4050×2800mm | ||||

| Machine weight | 13800kg | ||||

**Note: The above parameters are for reference only. Modifications or upgrades are available. Contact us directly for more information.

The QT10-15 concrete block making machine can make 10 blocks with dimensions of 400 x 200 x 200 mm with each mold. Within an 8 hour working day, the production volume reaches up to 16,000 blocks. A double lined aero vibration proof system is applied to this concrete block making machine to alleviate the vibrating impact on the mechanical parts, allowing the machine to work quieter and for longer periods of time.

As a block machinery manufacturer, we have specialized in developing and supplying automatic block machines for over 10 years. Along with the QT10-15 concrete block making machine, we have other models available for customers to choose from.

With more than 50 technicians and engineers on staff, we can offer on-site installation guidance, and help train your operators on correct machine operation and maintenance, in order to extend the service life of the concrete block making machine. Listed below are a few common maintenance tasks for the automatic brick making machine.

1. Replace the slide bushing used in the machine if it has been worn down too far.

2. Ensure that the amount of space between the tamper head and the mold box are roughly equal, in order to ensure a stable mold release.

3. Keep the material hopper pallet in the same plane as the mold.

4. Scrape residual raw material from the feed hopper after the hopper has been retracted. 4. Keep the scrapers in the proper position and replace them when necessary.

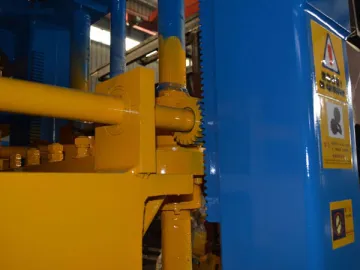

Pictures of Details

Host

Centralized lubrication system

Material loader 2

Touch screen of PLC

For more molds and samples, please click ""

Links:https://globefindpro.com/products/70486.html

-

Dry Barrel Fire Hydrant

Dry Barrel Fire Hydrant

-

Multifunctional Fluid Bed Granulator / Pelletizer / Coater

Multifunctional Fluid Bed Granulator / Pelletizer / Coater

-

Concrete Block Making Machine, QT9-15

Concrete Block Making Machine, QT9-15

-

Fluid Bed Coater

Fluid Bed Coater

-

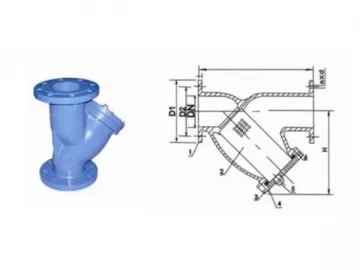

Y-Type Strainer

Y-Type Strainer

-

Fire Protection Swing Check Valve, Flanged End

Fire Protection Swing Check Valve, Flanged End

-

Center Line Butterfly Valve

Center Line Butterfly Valve

-

Stainless Steel Fittings

Stainless Steel Fittings

-

Concrete Block Making Machine, QT4-15

Concrete Block Making Machine, QT4-15

-

Stainless Steel Ball Valve

Stainless Steel Ball Valve

-

Valve Accessories

Valve Accessories

-

Fire Protection Gate Valve

Fire Protection Gate Valve