Exhaust Fan with Hammer Ball

Our exhaust fan with hammer ball has frames made from galvanized plates with fine layer of zinc covering them. The frames made by CNC machines imported from Germany in order to ensure that all the holes are punched in consistent sizes. Thanks to the fan blades that were designed in collaboration with Tshinghua University, this ventilation fan has a large air flow, low energy consumption and a long life. The large flow ventilator we produce is easy to install and of high quality, making it an international leader in the industry.

Application

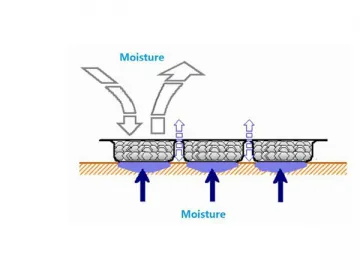

This exhaust fan with hammer ball we offer can be widely used in almost any industry requiring ventilation and cooling, like flower and plant growing, stock farming, textile, mining, chemical, medical, grain, tea, and wood.

Working Capacity

One exhaust fan with hammer ball is capable of exchanging 700m3 of indoor air with outdoor air nearly 63 times an hour. Employed with our design scheme, the indoor air speed of your workshop is roughly 3m/s.

Structural Features

Fan blade

In cooperation with Xi'an Jiaotong University and Tsinghua University, we have designed blades for the heavy hammer air fan. Having passed the dynamic balance test and the static balance test, the fan blades come with reasonable blade angles can produce large air flows with low noise levels.

Impeller and Fan Blade Base

The ventilation device we produce adopts impeller and fan blade base both made of aviation aluminum alloy. The belt pulleys are strong, feature a great tenacity, and long service life as they are designed with reinforcement and treated to sand blasting.

Motor

Motors used in our exhaust fan with hammer ball can be either Siemens or a Chinese brand, and the choice is up to the customer. They can also be customized according to voltage and frequency that the customer desires. The Chinese motors are equipped with a phase loss protection device which cuts off the power supply in the event phase loss occurs. Having passed the China Compulsory Certification, the motors of our heavy hammer exhaust fans are in accordance to the protection grades of IP55 and insulation class F.

Bearings

Our draught fans employs bearings imported from France. These bearings are strong, emit little noise, and have a long service life.

Triangular Belt

The triangular belt is imported from Japan, and has a lifespan 3 times longer than most of others of its kind and is configured with advanced automatic tensioning mechanisms, which gets rid of the need for manual belt tension adjustment.

Swing Heavy Hammer

Made of stainless steel, the shutters on our exhaust fan are resistant to wind, rain and dust. A unique heavy hammer mechanism is configured to the shutter, allowing it be opened at a 90 degree angle. Its design has been awarded a national patent.

Computer-Controlled Dynamic Balance Tester

Computer controlled dynamic balance testers are used to ensure that the entire shutter mounted exhaust fan has a higher stability, low noise emission and longer lifespan.

Belt Tensioning Mechanism

An advanced automatic tensioning mechanism is used to ensure great belt operation.

Hot Dipped Galvanized Pillar

The pillars of our exhaust fan with hammer balls are treated with a hot dipped galvanization, and won't get rusty in severe environments.

CNC Streamlined Production

Adopting streamlined production, we can guarantee our draught fan is highly qualified and has a beautiful appearance.

Technical Parameters of Exhaust Fan with Hammer Ball

| Model | DJF500 | DJF610 | DJF750 | QCHS760 | QCHS910 | QCHS1000 | QCHS1060 | QCHS1100 | QCHS1250 | QCHS1300 | QCHS1400 | QCHS1500 |

| Blade diameter (mm) | 500 | 610 | 750 | 760 | 910 | 1000 | 1060 | 1100 | 1250 | 1300 | 1400 | 1500 |

| Blade rotational speed (rpm) | 1400 | 960 | 660 | 630 | 480 | 500 | 500 | 480 | 439 | 439 | 420 | 430 |

| Motor rotational speed (rpm) | 1400 | 960 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 |

| Air flow (m3/h) | 9000 | 13000 | 17000 | 15000 | 20000 | 28000 | 30000 | 30000 | 43000 | 38000/45000 | 50000 | 58000 |

| Total pressure (Pa) | 55 | 75 | 60 | 65 | 70 | 70 | 73 | 73 | 56 | 56 | 60 | 60 |

| Noise (dB) | ≤70 | ≤70 | ≤60 | ≤65 | ≤70 | ≤70 | ≤70 | ≤70 | ≤70 | ≤65 | ≤70 | ≤70 |

| Input power (W) | 370 | 550 | 750 | 550 | 550 | 750 | 750 | 750 | 1100 | 750/1100 | 1500 | 1500 |

| Rated voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Height (mm) | 600 | 720 | 820 | 900 | 1000 | 1100 | 1180 | 1220 | 1380 | 1380 | 1530 | 1680 |

| Width (mm) | 600 | 720 | 820 | 900 | 1000 | 1100 | 1180 | 1220 | 1380 | 1380 | 1530 | 1680 |

| Thickness (mm) | 380 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

Installation Cases

Links:https://globefindpro.com/products/71810.html