Centrifugal Exhaust Fan

This type of exhaust fan is designed with a push/pull mechanism which can open and close the shutter automatically. All outer frames on our ventilation fans have reinforced ribbing to guarantee high strength and tightness. When compared with the exhaust fan with hammer ball, this draft fan with an automatic shutter can shade from light, wind resistance and heat insulation.

Applications

1. The ventilation fan we offer is appropriate for industrial production workshops that have high temperatures and unpleasant smells, such as textile factories, electronic factories and machinery manufacturing.

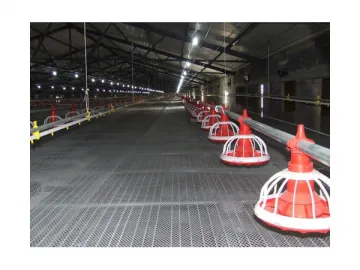

2. Our exhaust fans with automatic shutters can also be used in greenhouses, livestock breeding farms, and other places where heat preservation is needed during cold weather.

3. This ventilator is fit for using in almost any industry requiring cooling and ventilation.

Working Capacity

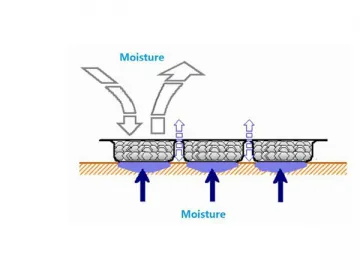

One set of exhaust fan is capable of exchanging 700m3 of indoor air with outdoor air at roughly 63 times an hour. Employed with design scheme we develop, the indoor air speed of your workshop is about 3m/s.

Structural Features

Fan Blades

The exhaust fan blades are made of Crupp self-cleaning stainless steel formed by dye punching. With a specially designed shape, these fan blades can achieve optimal working efficiency and produce a large air flow. The blades of our draft fan are also durable as they are difficult to deform, break or get dusty. The stainless steel we use is 1.2mm thick with a BA surface finish.

Centrifugal Push-Pull Mechanism

A centrifugal push-pull mechanism used in our product guarantees the shutter can be opened or closed completely, which minimizes the shutter opening resistance and maximizes the air flow of the exhaust fan. The centrifugal push-pull mechanism can also allow the shutter to close tightly, effectively keeping wind and light out of the room, ensuring great heat insulation effects during cold weather.

This mechanism is made of high quality PA66 nylon and has a long service life. Each part is connected by a copper rivet that is wear resistant, rust-resistant, and flexible, reducing friction and coefficients. The guide rod is made of 304 stainless steel added to other special materials to ensure the strength of the shutter, and feature excellent rust resistance and low friction coefficients.

Shutter Connection Fittings

Premium nylon connection fittings which are durable are used for the shutters for flexible openings. The shutter is made from hot galvanized steel plates, ranging in thickness from 0.8 mm to 1.5 mm thick. These high quality materials ensure the shutter stability and prevent blade deformation.

Belt

We use belts imported from the Japanese company Mitsubishi. These imported belts have a long service life and are maintenance free. In 2010, we replaced the A-type belt in our ventilation device with the B-type, whose lifespan is 3 times longer.

Motor

Motors installed on this fan are either from prominent Chinese manufacturers or Siemens, depending on the client's preferences and needs for voltage and frequency. The motors that are produced by the Chinese manufacturers are designed with a phase loss protection device. This will cut off the power if phase loss occurs. All motors we use conform to the IP55 protection grade and F-insulation class.

Fan Blade Pulley and Flange

The fan blade pulleys and flanges are made of a high strength aluminum magnesium alloy, and are manufactured using dye casting, which is light weight and causes very little vibration. Due to sand blasting and internal stress relieving, the fan blade pulleys and flanges always look nice and perform at high strengths.

Rivet Nut

As a professional ventilation equipment manufacturer, our company is one of the first in China to use a hexagon rivet nut rather than the circular rivet nut to fasten the motor hanging plate. We also use stainless steel gaskets to enhance the riveting strength

Housing

On both sides of this fan, there are plastic handles to facilitate machine movement. The handles are reasonably designed with a nice appearance and will not hurt your hands.

Pull Rod and Tension Spring

This centrifugal exhaust fans utilizes a lightweight, anti-deformation alloy pull rod. The pull rod is equipped with a wear-resistant sleeve, which helps improve fit clearance and the friction coefficient, making sure the shutter can open flexibly.

The tension spring is made from premium 304 stainless steel and will not become deformed or get rusty, even after prolonged periods of time.

Gasket

The gaskets used in our exhaust fans with automatic shutters are made from stainless steel, which gives them a nice appearance and will not rust.

Bearing

This fan uses double row bearings imported from France, and features excellent waterproof performance, high strength, low noise emission, a long service life and no maintenance.

Motor Hanging Plate

A specially designed multi-purpose motor hanging plate allows the user to install a 1 HP or 1.5 HP motor and ensures motor pulleys and fan pulleys are in a straight line. This reduces the wear on the triangular belt, extending its service life.

Fan Blade

The fan blades are calibrated using a computer controlled dynamic balance tester to guarantee the draught fan has a high stability, low vibration levels, and low noise emission while it's working. They can be made of stainless steel, galvanized sheets, or aluminum alloy sheets based on your requirements.

Pillar and Protection Wire Net

Our exhaust fans with automatic shutters use hot, galvanized pillar and protection wire nets for outstanding rust resistance.

Streamlined Production

CNC streamlined production enhances the quality and guarantees a beautiful appearance of our ventilation fans.

Technical Parameters of Centrifugal Exhaust Fan

| Model | QCHS-910 | QCHS-1250 | QCHS-1300 |

| Blade diameter (mm) | 910 | 1250 | 1300 |

| Blade rotational speed (rpm) | 438 | 460 | 439 |

| Motor rotational speed (rpm) | 1400 | 1400 | 1400 |

| Air flow (m3/h) | 21000 | 44000 | 45000 |

| Total pressure (Pa) | 57 | 57 | 57 |

| Noise (dB) | ≤65 | ≤65 | ≤65 |

| Input power (W) | 550 | 1100 | 1100 |

| Rated voltage (V) | 380 | 380 | 380 |

| Height (mm) | 1000 | 1380 | 1380 |

| Width (mm) | 1000 | 1380 | 1380 |

| Thickness (mm) | 450 | 450 | 450 |

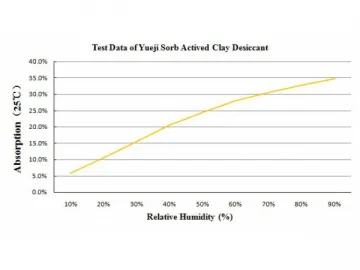

Air Flow Curve Chart

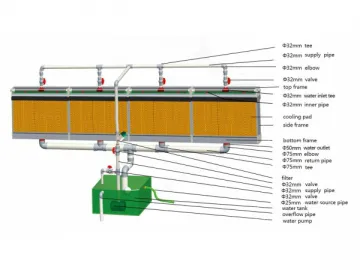

Installation Cases

Links:https://globefindpro.com/products/71816.html