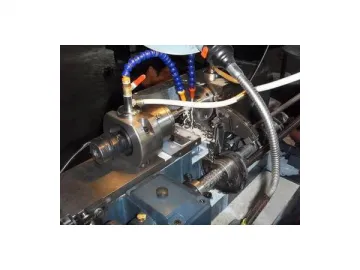

Ultrasonic Transducer for Welding, Drilling and Polishing

The ultrasonic transducer for welding, drilling and polishing uses local high temperature brought by high frequency vibration (tens of thousands of times per second) to weld, drill and polish plastics and other materials, which is environment-friendly and energy-saving.

With the continuous innovation on ultrasonic technology ( like ultrasonic welding technology), significant advancement on quality and satisfactory improvement on precision, the high power piezoelectric ceramic transducer is extensively applied in many industries like electronics, home appliance, toy, plastic, automotive, communication, medicine, packaging, etc. And it is well suitable for ultrasonic plastic welder, ultrasonic driller, ultrasonic polisher (like ultrasonic mould polisher) and other ultrasonic transducer equipment.

Ultrasonic transducer is the core component that converts electrical energy into mechanical energy (ultrasound).To ensure strong and stable ultrasonic power output, our high power ultrasonic transducer is equipped with imported top-notch piezoelectric ceramics. Besides, we can also supply ultrasonic driller components (like ultrasonic generator and drill bit) and other ultrasonic equipment components.

Features

1. High efficiency: The mechanical energy loss is small and the electro-acoustic conversion efficiency is extremely high.

2. High amplitude: the structure design is optimized by computer to achieve high vibration frequency, high mechanical Q factor and slow attenuation.

3. Large power: pre-stressed auger-type piezoelectric ceramic gives full play to its energy.

4. Great heat resistance: the operating temperature range is wide, the resonant impedance is low, and the transducer can work continuously for a long time with minimal heat dissipation.

Technical Parameters of Ultrasonic Transducer for Welding, Drilling and Polishing

| Model | Total length (mm) | Connection tap | Frequency (KHz) | Resonant impedance (Ω) | Capacitance (PF) | Input power (W) |

| CCH-7070F-15Z P8 | 153 | M20 P1.5 | 15 | 15 | 13000 | 2500 |

| CCH-6060F-15Z P8 | 167 | M20 P1.5 | 15 | 10 | 9500 | 2000 |

| CCH-5050F-15Z P4 | 171 | M18 P1.5 | 15 | 12 | 12500 | 1500 |

| CCH-6060F-20Z P4 | 118 | M20 P1.5 | 20 | 15 | 15000 | 1800 |

| CCH-5555F-20Z P8 | 128 | M18 P1 | 20 | 10 | 11000 | 2000 |

| CCH-5050F-20Z P8 | 124 | M18 P1.5 | 20 | 12 | 10000 | 1500 |

| CCH-4040F-20ZL P8 | 112 | 1/2-20 UNF | 20 | 15 | 9000 | 700 |

| CCH-4040F-20ZL-P P8 | 133 | 1/2-20 UNF | 20 | 15 | 10000 | 900 |

| CCH-5050D-20D-P P8 | 121 | M18 F1.5 | 20 | 15 | 6000 | 600 |

| CCH-3030F-30Z P8 | 77 | M10 F1.5 | 30 | 5 | 5500 | 500 |

| CCH-3030D-28Z P4 | 92.1 | M10 F1 | 28 | 20 | 3000 | 200 |

| CCH-2525D-28Z P8 | 91 | M8 F1 | 28 | 25 | 2200 | 100 |

| CCH-3838D-28ZL P8 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| CCH-3850L-20D P8 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| CCH-3840L-20D P8 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| CCH-3850F-20D P8 | 128 | 1/2-20 UNF | 20 | 10 | 12500 | 1300 |

| CCH-3850F-20DL P8 | 132 | 1/2-20 UNF | 20 | 10 | 11000 | 1500 |

| CCH-3840F-20D P8 | 123 | 1/2-20 UNF | 20 | 10 | 9500 | 900 |

| CCH-5060F-15D P4 | 171 | M18 1.5F | 15 | 12 | 10000 | 2000 |

| CCH-2525D-35ZL P8 | 71 | M8 1F | 35 | 25 | 2200 | 100 |

| CCH-2020D-38ZL P8 | 66 | M8 1.25F | 38 | 40 | 1200 | 100 |

| CCH-2830D-38DL P4 | 65 | M8 1F | 38 | 14 | 3300 | 200 |

Links:https://globefindpro.com/products/74961.html

-

Ultrasonic Transducer for Beauty Equipment

Ultrasonic Transducer for Beauty Equipment

-

Poly-cotton Tablecloths and Chair Cover

Poly-cotton Tablecloths and Chair Cover

-

Wool Blanket

Wool Blanket

-

Longitudinal Submerged Arc Welded Pipe (LSAW Steel Pipe)

Longitudinal Submerged Arc Welded Pipe (LSAW Steel Pipe)

-

Ultrasonic Transducer for Collar Cleaning

Ultrasonic Transducer for Collar Cleaning

-

Ultrasonic Cell Disruptor

Ultrasonic Cell Disruptor

-

Ultrasonic Transducer for Cleaning

Ultrasonic Transducer for Cleaning

-

Yarn Dyed Towel

Yarn Dyed Towel

-

Ultrasonic Generator

Ultrasonic Generator

-

Ultrasonic Transducer for Vibration Screen

Ultrasonic Transducer for Vibration Screen

-

Hand Towel

Hand Towel

-

Cotton Tablecloth and Chair Cover

Cotton Tablecloth and Chair Cover