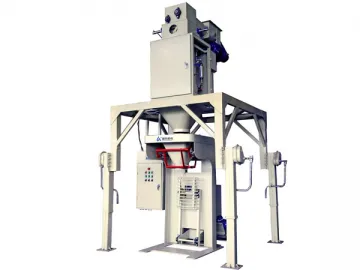

DCS2F Weigh Filler for Powder

The DCS2F weigh filler for powder has emerged as the specialized weighing solution applied to solid particle or powder for industries of chemicals, pharmaceuticals, grain and oil, etc. Our weighing and packing line mainly consists of feeding unit, weighing unit, display system, control system, actuator and structural parts.

Advantage

1. Grounded on compacted structure and easy installation, this weigh filler for powder shows exceptional resilience to various requirements on working condition and productivity.

2. In order to keep clean environment, our powder filling equipment involves the usage of dust collecting device to collect pollution generated during production process.

3. This weigh filler comes with impressive filling range from 800 to 2000g. The production rate reaches 300 to 500 bags per hour. Therefore, our packaging machine is perfect for powder materials featuring poor flow characteristics and certain stickiness, such as feed additive, special flour, protein powder, milk powder and soft sugar.

| Production rate | 300 to 500 bags/h | ||

| Filling range | 800 to 2000g | ||

| Filling accuracy | × (0.2) level | ||

| Main motor power | 1600W | Air supply pressure | 0.6MPa |

| Applicable materials | Powder materials featuring poor flow characteristics and certain stickiness, such as feed additive, special flour, protein powder, milk powder and soft sugar. | ||

| Structure features | 1. Gravimetric weighing 2. Vertical auger feeding system with variable frequency 3. Dust collecting device for environment protection | ||

Links:https://globefindpro.com/products/75886.html

-

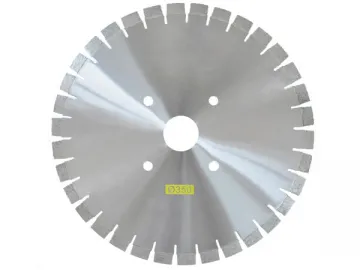

Cured Concrete Diamond Blade

Cured Concrete Diamond Blade

-

DCS50S-2 High Speed Weigh Filler for Granule

DCS50S-2 High Speed Weigh Filler for Granule

-

NTBF Series VFFS Machine for Stand up Pouch

NTBF Series VFFS Machine for Stand up Pouch

-

DCS25MF Weigh Filler for Powder

DCS25MF Weigh Filler for Powder

-

DCS50HF Weigh Filler for Powder

DCS50HF Weigh Filler for Powder

-

NTBH Series Medium Speed VFFS Machine

NTBH Series Medium Speed VFFS Machine

-

Check Weigher

Check Weigher

-

NTHSC-560 VFFS Machine with Rotary Jaw

NTHSC-560 VFFS Machine with Rotary Jaw

-

Bag Filling and Sealing Machine

Bag Filling and Sealing Machine

-

Bushing

Bushing

-

Granite Diamond Blade

Granite Diamond Blade

-

NTHSD-510 VFFS Machine with Reciprocating Jaw

NTHSD-510 VFFS Machine with Reciprocating Jaw