NTBH Series Medium Speed VFFS Machine

The NTBH series medium speed VFFS machine is the intermittent motion package equipment with maximal 60 bags/m production rate.

Advantage

1. This bag making machine is endowed with stainless steel housing for reduced overall weight and prominent resistance against corrosion.

2. PLC and touch screen deliver intuitive operation.

3. This VFFS machine utilizes servo motor to control film pulling motion for superior packaging effect.

4. Synchronous motion is maintained between coding machine and film feeding unit to further ensure flawless bags.

5. Photoelectric control is responsible for precise cutting.

Application

Our automatic packaging system is well-suited for all kinds of bulk solids, powders, fluids and paste-like materials such as puffed grain food, dried fruit, sugar, salt, vinegar, beverage, sauce, small hardware, etc.

| Optional feeding system1. Auger feeding system2. Cup feeding system3. Linear scale4. Combination scalePackage material1. Single layer PE film2. Multi-layer heat-sealing composite filmBag type1. Standard pillow pack2. Gusseted bag3. PE bag4. Square bottom bag5. Perforated rolls | Optional device1. Air/nitrogen charging equipment2. Gusset forming device3. Air exhausting device4. Punching device5. Perforated lip maker6. Jam-preventing equipment7. Safety equipment8. Bag support 9. PE sealing machine10. Vacuum pump11. Flip device12. Static electricity eliminator 13. Creasing device14. Guide device15. Special sealing jaw |

Specification

| Model | BH-500 | BH-620 | BH-800 |

| Film width | 180 to 500mm | 220 to 620mm | 340 to 800mm |

| Bag width | 80 to 240mm | 100 to 300mm | 160 to 385mm |

| Bag length | 100 to 300mm | 100 to 380mm | 100 to 480mm |

| Production rate | 15 to 60 bags/m | 15 to 60 bags/m | 10 to 30 bags/m |

| Air supply | 0.36m3/min, 0.6Mpa | 0.4m3/min, 0.6MPa | 0.7m3/min, 0.6Mpa |

| Power supply | 220V, 50HZ, 3kW | 220V, 50HZ, 4 kW | 220V, 50HZ, 4.5 kW |

| Machine weight | 550kg | 680kg | 980kg |

| Overall dimension | 1550 × 1160 × 1480mm | 1600 × 1260 × 1680mm | 1600 × 1500 × 2050mm |

Links:https://globefindpro.com/products/75892.html

-

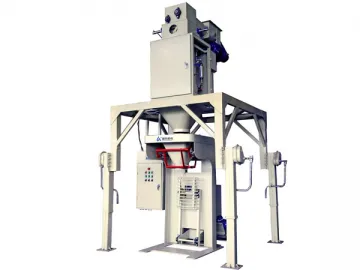

DCS50S Weigh Filler for Granule

DCS50S Weigh Filler for Granule

-

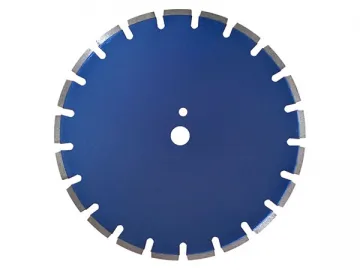

Asphalt Diamond Blade

Asphalt Diamond Blade

-

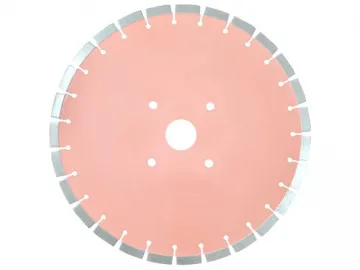

Green Concrete Diamond Blade

Green Concrete Diamond Blade

-

Sandstone Diamond Blade

Sandstone Diamond Blade

-

NTBL Series VFFS Machine for Large Pouch

NTBL Series VFFS Machine for Large Pouch

-

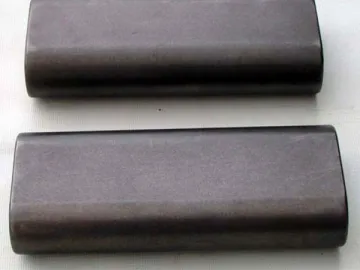

Chisel Pin

Chisel Pin

-

DCS50HF Weigh Filler for Powder

DCS50HF Weigh Filler for Powder

-

DCS25MF Weigh Filler for Powder

DCS25MF Weigh Filler for Powder

-

NTBF Series VFFS Machine for Stand up Pouch

NTBF Series VFFS Machine for Stand up Pouch

-

DCS50S-2 High Speed Weigh Filler for Granule

DCS50S-2 High Speed Weigh Filler for Granule

-

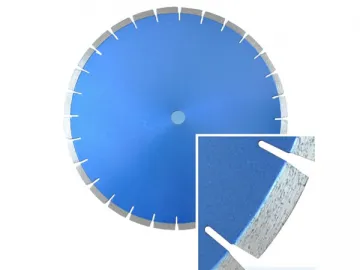

Cured Concrete Diamond Blade

Cured Concrete Diamond Blade

-

DCS2F Weigh Filler for Powder

DCS2F Weigh Filler for Powder