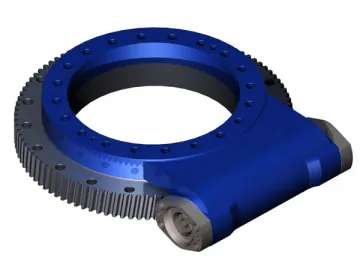

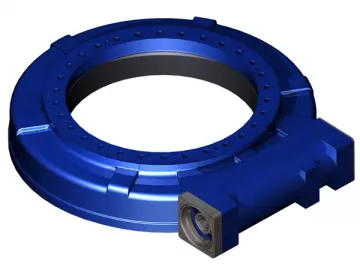

MT Series Four Point Contact Ball Bearing

1. Description

Our MT series four point contact ball bearing boasts high cost-performance. Its cross section is rectangular and its outer diameter ranges from 4 inches to 47 inches, i.e., 100 mm to 1200 mm.

2. Features

a. Due to the adoption of deep groove raceway and balls of the maximum size, this series of slewing bearing is able to withstand higher torque, thrust, and radial load than ordinary four point contact ball bearings.

b. The deep groove ball bearing is designed with large seal and non-contact dust cover for its groove. This helps block contaminants to some extent and makes our slew ring bearing perform well in many different application environments, from light load to heavy load.

c. This rolling element bearing is available in no tooth type and external tooth type. Double involute short-tooth gear is adopted.

3. Supply Capacity

The MT series four point contact ball bearing is belongs to a conventional product. Hence, we can offer this product within the shortest time. In addition, non-standard screw hole and gear parameters can be customized.

4. Application

The four point contact ball bearing is widely used in many occasions from light load to heavy load.

For small size product:

a. Mechanical arm

b. Jib crane

c. Auxiliary lifting equipment

d. Workpiece positioner

For large size product

a. Lifting crane

b. Cable car / elevator

c. Crane

d. Small wind turbine

e. Non-precision positioning table

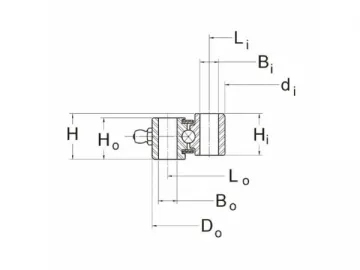

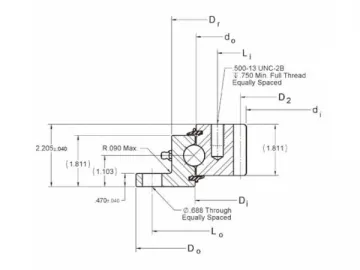

5. Technical Parameters

| No Gear | ||||||||||||

| P/N | OUTLINE DIMENSIONS AND WEIGHT | MOUNTING HOLES | MOMENT RATING Crm (ft-lbs) | |||||||||

| OUTER RING | INNER RING | |||||||||||

| Do | di | H | Hi /H o | G APPROX. | Lo | no | Bo | Li | ni | Bi | ||

| (in) | (in) | (in) | (in) | (lbs) | (in) | (in) | (in) | (in) | ||||

| MTO-050 | 4.331 | 1.968 | 0.787 | 0.728 | 2 | 3.818 | 8 | 0.26 | 2.48 | 8 | 0.26 | 830 |

| MTO-050T | 4.331 | 1.968 | 0.787 | 0.728 | 2 | 3.818 | 8 | M6 | 2.48 | 8 | M6 | 830 |

| MTO-065 | 5.315 | 2.559 | 0.866 | 0.787 | 4 | 4.724 | 8 | 0.354 | 3.149 | 8 | 0.354 | 1,330 |

| MTO-065T | 5.315 | 2.559 | 0.866 | 0.787 | 4 | 4.724 | 8 | M8 | 3.149 | 8 | M8 | 1,330 |

| MTO-122 | 8.898 | 4.803 | 1.339 | 1.142 | 13 | 8.189 | 12 | 0.354 | 5.512 | 12 | 0.354 | 5,020 |

| MTO-122T | 8.898 | 4.803 | 1.339 | 1.142 | 13 | 8.189 | 12 | M8 | 5.512 | 12 | M8 | 5,020 |

| MTO-143 | 9.803 | 5.63 | 1.339 | 1.142 | 15 | 8.937 | 12 | 0.433 | 6.496 | 12 | 0.433 | 8,950 |

| MTO-143T | 9.803 | 5.63 | 1.339 | 1.142 | 15 | 8.937 | 12 | M10 | 6.496 | 12 | M10 | 8,950 |

| MTO-145 | 11.811 | 5.709 | 1.968 | 1.732 | 37 | 10.63 | 16 | 0.562 | 6.89 | 16 | 0.562 | 26,000 |

| MTO-145T | 11.811 | 5.709 | 1.968 | 1.732 | 37 | 10.63 | 16 | 5/8-11 | 6.89 | 16 | 5/8-11 | 26,000 |

| MTO-145X | 12.286 | 5.709 | 1.968 | 1.732 | 41 | 10.63 | 16 | 0.594 | 6.89 | 16 | 0.594 | 30,600 |

| MTO-170 | 12.205 | 6.693 | 1.811 | 1.614 | 33 | 11.024 | 12 | 0.512 | 7.874 | 12 | 0.512 | 16,520 |

| MTO-170T | 12.205 | 6.693 | 1.811 | 1.614 | 33 | 11.024 | 12 | M12 | 7.874 | 12 | M12 | 16,520 |

| MTO-210 | 14.37 | 8.268 | 1.575 | 1.496 | 38 | 13.19 | 16 | 0.562 | 9.449 | 20 | 0.562 | 44,500 |

| MTO-210T | 14.37 | 8.268 | 1.575 | 1.496 | 38 | 13.19 | 16 | 5/8-11 | 9.449 | 20 | 5/8-11 | 44,500 |

| MTO-210X | 14.686 | 8.268 | 1.968 | 1.732 | 48 | 13.19 | 16 | 0.594 | 9.449 | 20 | 0.594 | 52,100 |

| MTO-265 | 16.535 | 10.433 | 1.968 | 1.732 | 54 | 15.354 | 18 | 0.562 | 11.614 | 24 | 0.562 | 62,000 |

| MTO-265T | 16.535 | 10.433 | 1.968 | 1.732 | 54 | 15.354 | 18 | 5/8-11 | 11.614 | 24 | 5/8-11 | 62,000 |

| MTO-265X | 17.086 | 10.433 | 1.968 | 1.732 | 61 | 15.354 | 18 | 0.594 | 11.614 | 24 | 0.594 | 71,900 |

| *MTO-324T | 20.486 | 12.75 | 2.062 | 2.022 | 105 | 18.875 | 20 | 5/8-11 | 14.375 | 20 | 5/8-11 | 102,400 |

| MTO-324X | 20.486 | 12.77 | 2.375 | 2.063 | 105 | 18.875 | 20 | 0.688 | 14.375 | 20 | 0.688 | 102,400 |

Links:https://globefindpro.com/products/76740.html

-

S Series Single Worm Slewing Drive

S Series Single Worm Slewing Drive

-

Silk Satin

Silk Satin

-

Horizontally Mounted Worm Drive

Horizontally Mounted Worm Drive

-

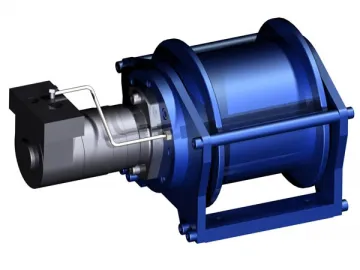

Hydraulic Winch

Hydraulic Winch

-

SE-2 Series Dual Worm Slewing Drive

SE-2 Series Dual Worm Slewing Drive

-

Doupion Silk Yarn

Doupion Silk Yarn

-

Silk Quilts

Silk Quilts

-

Thrown Silk Yarn

Thrown Silk Yarn

-

Ultra-Thin X-Ray Film Viewer

Ultra-Thin X-Ray Film Viewer

-

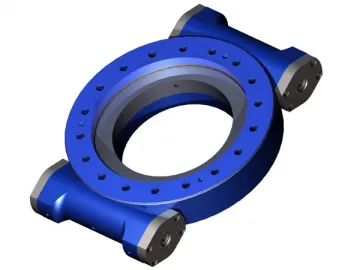

RK Series Four Point Contact Ball Bearing

RK Series Four Point Contact Ball Bearing

-

HSE Series Single Worm Slewing Drive

HSE Series Single Worm Slewing Drive

-

UV Air Purifiers

UV Air Purifiers