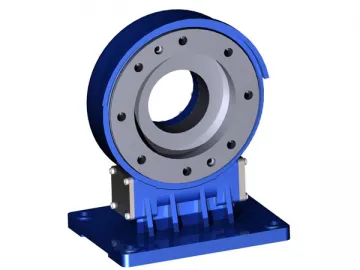

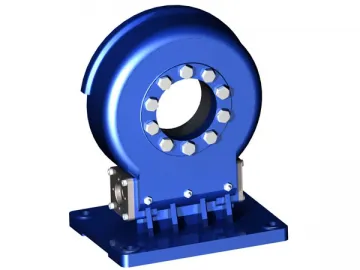

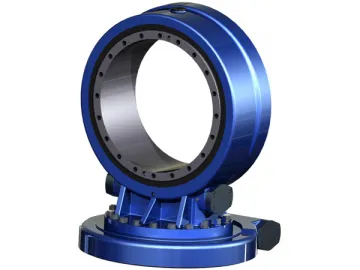

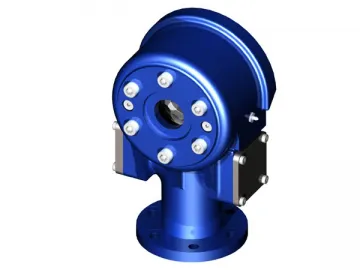

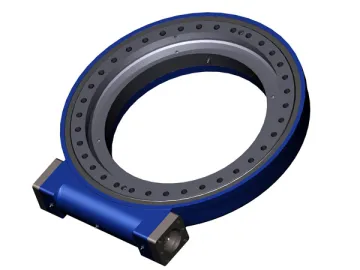

HS Series Four Point Contact Ball Bearing

1. Description

The HS series four point contact ball bearing is similar to the RK series except that it has a rectangular cross-section. This rolling element bearing is designed with multiple spare holes which can improve stiffness so as to yield better performance. Our product is available with the outside diameter of 20 to 47 inches.

2. Features

a. Designed with deep groove raceway and balls of the maximum size, our deep groove ball bearing can withstand higher torque, thrust, and radial load than ordinary products.

b. Perfect sealing helps discharge dirt and impurities.

c. The bearing bush ring with teeth is designed with tapered bores while the one without teeth adopts through holes.

d. This series of four point contact ball bearing is available in internal tooth type, external tooth type, and no tooth type. The gear adopts involute short tooth design. The pressure angle is 20 degrees and the permissible backlash is 0.015 to 0.025 inches.

e. All slewing bearings of the HS series have two grease nipples spaced by 180 degrees. For the no tooth type and internal tooth type, the grease nipple is located in the outer ring. While for the external tooth type, the nipple is in the inner ring.

3. Supply Capacity

We are capable of providing HS series four point contact ball bearing with the most reliable quality in the shortest possible time. The threaded holes and gear parameters can be customized.

4. Application

This series of four point contact ball bearing is extensively applied in the occasions of medium or heavy loads, including

a. Crane

b. Cable cars / elevators

c. Excavator derrick

d. Rotary chute

e. Turntable of lift truck

f. Industrial rotary table

5. Technical Parameters

| No Gear | ||||||||||||

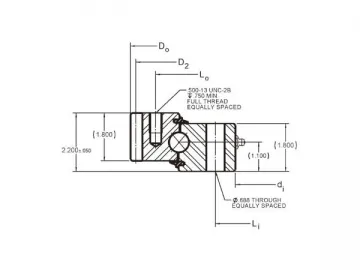

| P/N | OUTLINE DIMENSIONS AND WEIGHT | MOUNTING HOLES | GEAR DATA INV. STUB, α = 20° | MOMENT RATING Crm | ||||||||

| OUTER RING | INNER RING | |||||||||||

| Do | di | G APPROX. | Lo | no | Li | ni | D2 | Pd | z2 | Fz | ||

| (in) | (in) | (lbs) | (in) | (in) | (in) | (lbs) | (ft-lbs) | |||||

| HS6-16P1Z | 20.400 | 12.000 | 103 | 19.000 | 8 | 13.5 | 12 | — | — | — | — | 50,500 |

| HS6-21P1Z | 25.500 | 17.000 | 137 | 24.000 | 12 | 18.5 | 15 | — | — | — | — | 72,700 |

| HS6-25P1Z | 29.500 | 21.000 | 162 | 28.000 | 15 | 22.5 | 18 | — | — | — | — | 91,800 |

| HS6-29P1Z | 33.400 | 25.000 | 186 | 32.000 | 15 | 26.5 | 18 | — | — | — | — | 111,900 |

| HS6-33P1Z | 37.400 | 28.830 | 216 | 35.750 | 18 | 30.5 | 20 | — | — | — | — | 128,000 |

| HS6-37P1Z | 41.250 | 32.830 | 233 | 39.750 | 18 | 34.38 | 20 | — | — | — | — | 130,900 |

| HS6-43P1Z | 47.180 | 38.750 | 269 | 45.620 | 20 | 40.25 | 24 | — | — | — | — | 139,900 |

Links:https://globefindpro.com/products/76759.html