2000watt Fiber Laser Cutting Machine

Model: TH-GDF3015-2000/TH-GDF4020-2000

Introduction

1. The bed and crossbeam of the high-speed fiber laser cutting machine are molded after the second high-precision process. So the machine shows good rigidity and stability.

2. Dual imported AC servo motors work synchronously and smoothly.

3. The constant light path structure is adopted for optical fiber transmission, to ensure consistent cutting results.

4. The optical system adopts imported cutting lens and drawer lens base, to ensure the cleanness, durability and precision of lens.

5. The laser cutting head of this fiber laser cutting machine can withstand a maximum air pressure of 2.3Mpa. The air pressure can be adjusted to fit for cutting different materials in various thicknesses.

6. The cutting head also has highly sensitive imported non-contact capacitive tracking system. The system and the sheet maintain a strict consistency, which ensures accurate cutting without damage to the cutting head caused by collision.

7. This fiber laser cutter has quick switch function between multi focal lengths 5 "and 7.5" for the fine cutting of both thin and thick materials. It is fast for changeovers. The operator can freely switch to a different thickness at any time.

Application

The high-speed fiber laser cutting machine is usually used for continuous cutting of metal sheets.

It is commonly used on the materials of aerospace aluminum, titanium alloy, stainless steel and mild steel, like the thin sheet cutting in areas of shipbuilding, railway, locomotive, automotive, pressure vessels, electrical cabinets, and white goods.

Technical Data| Specification/Model | TH-GDF3015-2000 / TH-GDF4020-2000 |

| Laser Power | 2000 Watts |

| Cutting Speed | 22m/min/1mmThickness |

| Idle Stroke Speed | 150m/min |

| Max. Cutting Thickness | 16mm carbon steel |

| Cutting Precision | ±0.2mm/300mm/1mmThickness |

| Cutting Area | 3000x1500mm, 4000x2000mm |

| Work Table | Dual Exchangeable Work Table |

| Cutting Head | Height can be adjustable automatically. |

| Control System | PA 8000 |

| Drive System | Portal Type, Servo Motor & Precision Rack and Pinion |

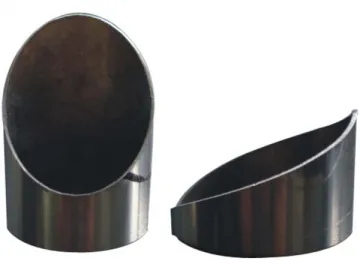

Sample

Pipe cross-section cutting Carbon steel cutting

Links:https://globefindpro.com/products/77043.html

-

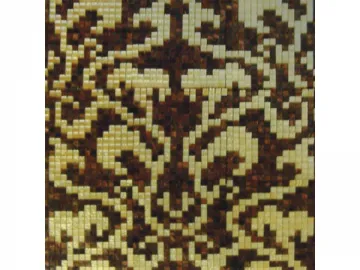

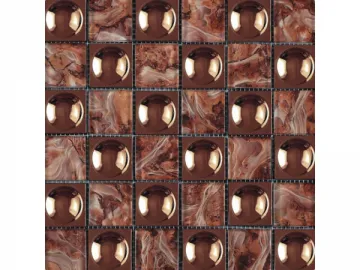

Indoor Glass Mosaic Tiles

Indoor Glass Mosaic Tiles

-

Indoor Glass Mosaic Tiles

Indoor Glass Mosaic Tiles

-

57mm Diameter Aerosol Can

57mm Diameter Aerosol Can

-

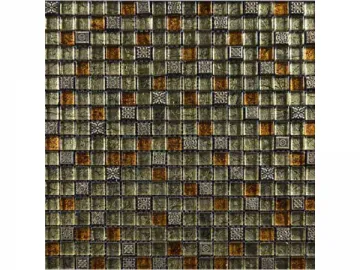

Kitchen Glass Mosaic Tiles

Kitchen Glass Mosaic Tiles

-

Indoor Glass Mosaic Tiles

Indoor Glass Mosaic Tiles

-

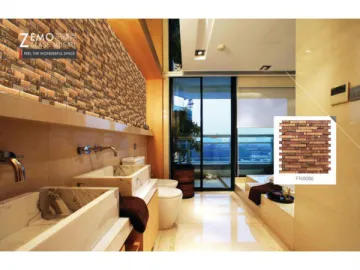

Bathroom Glass Mosaic Tiles

Bathroom Glass Mosaic Tiles

-

Indoor Glass Mosaic Tiles

Indoor Glass Mosaic Tiles

-

Laser Marking Machine for Bearing

Laser Marking Machine for Bearing

-

Restaurant Glass Mosaic Tiles

Restaurant Glass Mosaic Tiles

-

52mm Diameter Aerosol Can

52mm Diameter Aerosol Can

-

Bathroom Glass Mosaic Tiles

Bathroom Glass Mosaic Tiles

-

Suspension Type Laser Marking Machine

Suspension Type Laser Marking Machine