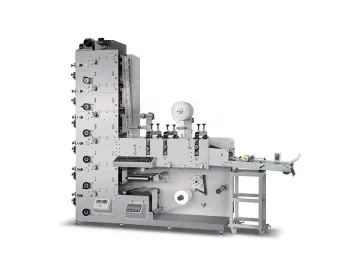

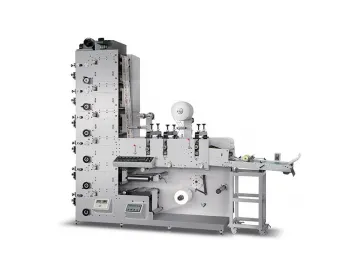

Flexo Printing Machine, ZBS-850

This product has been discontinued and removed from our shelves. Characteristic

This flexo printing machine adopts the ceramic anilox cylinder to transfer the ink.

Unwinding and rewinding tension are auto-controlled by tension controller.

Each printing unit adopts 3600 plate-adjustment.

IR dryer (hot air type) for each printing unit.

The ink rollers will be separated from the printing roller, and keep running when the machine stopped.

This series of flexo printing machine is mainly used for printing paper cups and packaging labels.

The machine can finish material-feeding, printing, drying and rewinding in a lump.

Main technical specification

Optional auxiliary equipment  Electric web-guiding system

Electric web-guiding system

Video system

Big unwinder&rewinder with diameter of 900mm Main equipment

This flexo printing machine adopts the ceramic anilox cylinder to transfer the ink.

Unwinding and rewinding tension are auto-controlled by tension controller.

Each printing unit adopts 3600 plate-adjustment.

IR dryer (hot air type) for each printing unit.

The ink rollers will be separated from the printing roller, and keep running when the machine stopped.

This series of flexo printing machine is mainly used for printing paper cups and packaging labels.

The machine can finish material-feeding, printing, drying and rewinding in a lump.

Main technical specification

| Printing speed | 50m/min |

| Printing color | 5colours |

| Max. width of paper | 850mm |

| Max .printing width | 820mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 600mm |

| Printing length | Z56-112/Z65-145/Z75-170 |

| Precision of chromatography | ±0.15mm |

| Dimensions | 3.45mX1.9m X2.5m (LXWXH) |

| Machine weight | About 4300kg |

There are several options for this flexo printing machine.

Video system

Big unwinder&rewinder with diameter of 900mm Main equipment

| The main equipment of our flexo printing machine is listed below. | |

| Printing roller: 3sets, the size is determined by the user. | |

| Anilox cylinders: 1set, the lines can be chosen from 200 to 800 by the user. | |

| Plate mounting machine: 1set | |

| Unwind tension controller: 1piece | Mitsubishi of Japan |

| Sensor: 2pcs | Mitsubishi of Japan |

| Rewind tension controller: 1piece | Made in china |

| Magnetic power brake: 2pcs | Ningxia, China |

| Electromagnetism valve: SMC 1piece | Japan |

| Inverter: TECO Brand | Taiwan (stop automatic when paper lack) |

| Contactor: Schneider | France |

| Center relay: Schneider | France |

| Temperature controller | Yuyao in Zhejiang |

| All switches: Schneider | France |

| Other low-pressure wiring | Schneider, France/ Yaohua, China |

Scan QR to Read

Links:https://globefindpro.com/products/7895.html

Links:https://globefindpro.com/products/7895.html

Recommended Products

-

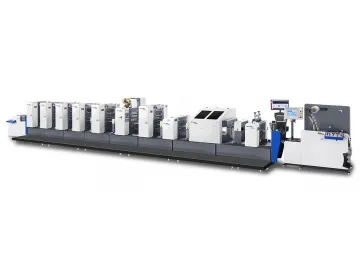

Offset Printing Machine, ZX-320

Offset Printing Machine, ZX-320

-

Signal Generator, ASG10

Signal Generator, ASG10

-

Label Inspection Machine, EM-450

Label Inspection Machine, EM-450

-

Flexo Printing Machine,ZBS-320 (1/2/3 Colors)

Flexo Printing Machine,ZBS-320 (1/2/3 Colors)

-

Label Inspecting Machine, EM-520

Label Inspecting Machine, EM-520

-

Slitting Machine with Rotary Die Cutting Station, DK-450G

Slitting Machine with Rotary Die Cutting Station, DK-450G

-

Flexo Printing Machine with Single Rotary Die Cutting Station, ZBS-450

Flexo Printing Machine with Single Rotary Die Cutting Station, ZBS-450

-

Medical Intelligent Insulation Monitor, AIM-M200

Medical Intelligent Insulation Monitor, AIM-M200

-

Slitting Machine with Rotary Die Cutting Station, DK-320G

Slitting Machine with Rotary Die Cutting Station, DK-320G

-

Flexo Printing Machine, ZBS-320G (3/4/5/6 Colors)

Flexo Printing Machine, ZBS-320G (3/4/5/6 Colors)

-

Flexo Printing Machine with Tripe Rotary Die Cutting Stations, ZBS-320G

Flexo Printing Machine with Tripe Rotary Die Cutting Stations, ZBS-320G

-

Flexo Printing Machine, ZBS-450G

Flexo Printing Machine, ZBS-450G

Hot Products