Microwave High Temperature Furnace

Introduction

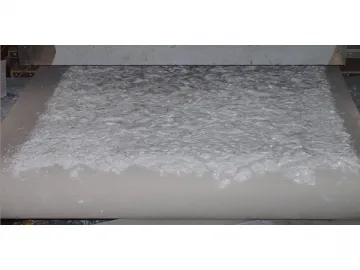

The microwave high temperature furnace is a new generation standard high-temperature experimental station integrated with the functions of muffle furnace and ashing furnace. As an environmental, energy-efficient microwave sintering furnace, it offers calcination, roasting, sintering, ashing, fusion, high-temperature synthesis, or thermal treatment solutions in all kinds of application environment. This microwave furnace is the ideal equipment for experiments and small production.

Advantages

1. With the dedicated high performance industrial microwave source, the microwave high temperature furnace can be continuously, stably operated for a long time.

2. It uses microwave energy to speed up the sintering and ensure the material thermal uniformity.

3. It enables the temperature to rise speedily, so as to greatly shorten the soaking time. Efficiency of experiments will be doubled.

4. Its microwave output power is adjustable for precise temperature control curve.

5. An imported high precision infrared thermometer is configured for direct sample temperature measurement.

6. The microwave furnace is installed with an embedded microcomputer control system. The system permits stable, precise temperature control. Its control precision is ±1℃.

7. Due to the unique dedicated crucible and insulation structure, it won't pollute materials.

8. The microwave high temperature furnace is compatible with various materials. Its user-friendly human-machine interface makes operation extremely easy.

9. It is suitable for inert gas protection experiment, as it has both inlet and outlet passages.

10. Corrosion resistant exhaust passage is set to speedily discharge the gas generated in the heating process.

11. Multiple protective devices such as safety locks are available. The high temperature furnace won't start its microwave function when the furnace door or heating chamber door is open or opened abnormally.

12. This microwave furnace has zero microwave leakage. It applies the safe, reliable microwave shielding design, ensuring the health and safety of operators.

Application

The microwave high temperature furnace is suitable for the sintering experiments of fine products including powder metallurgy, magnets, structural ceramics, piezoresistor, thermistor, piezoelectric ceramics, microwave dielectric ceramics, honeycomb ceramics, electrical porcelain, domestic ceramic, carbon materials, catalyst, high purity alumina, magnesium oxide, zinc oxide, zirconium oxide, aluminium hydroxide, zirconium nitrate, etc. Also, it is ideal for power products including rare earth luminescent material, battery material, ceramic pigment, glaze materials, inorganic pigment, barium titanate, barium strontium titanate, strontium titanate, barium zirconate titanate, metal carbide, among others. Last but not the least, it can be applied as dental zirconia sintering furnace.

Many varieties are available for your choice. Examples are domestic ceramic sintering furnace, battery materials sintering furnace, catalyst sintering furnace, sintering furnace for powder metallurgy, and many others.

Links:https://globefindpro.com/products/79004.html

-

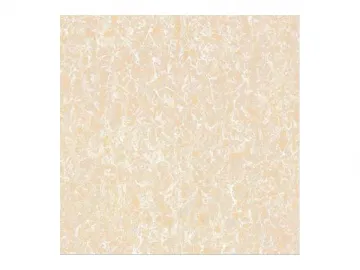

Netturo Polished Porcelain Tiles

Netturo Polished Porcelain Tiles

-

Heat Pump Seafood Dryer

Heat Pump Seafood Dryer

-

CNC Skiving and Roller Burnishing Machine

CNC Skiving and Roller Burnishing Machine

-

Double Action Hydraulic Cylinder

Double Action Hydraulic Cylinder

-

Borescope with LCD Display

Borescope with LCD Display

-

Piston Rod

Piston Rod

-

Microwave Vacuum Dryer

Microwave Vacuum Dryer

-

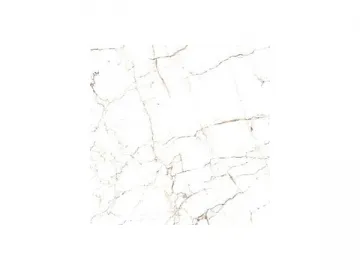

Super White Body Polished and Glazed Porcelain Tile

Super White Body Polished and Glazed Porcelain Tile

-

Mosaic Tiles

Mosaic Tiles

-

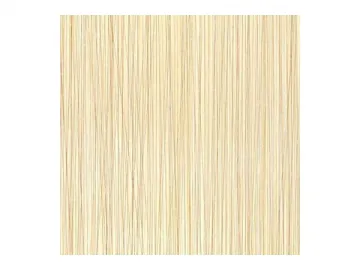

Linen Glazed Porcelain Tiles

Linen Glazed Porcelain Tiles

-

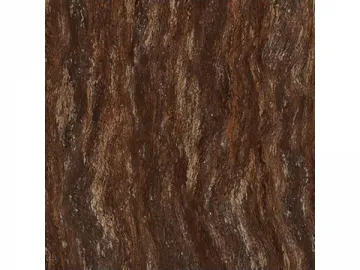

Brati Polished Porcelain Tiles

Brati Polished Porcelain Tiles

-

Microwave Chemical Material Dryer

Microwave Chemical Material Dryer