CNC Skiving and Roller Burnishing Machine

The CNC skiving and roller burnishing machine is a new machine that developed on our own. During the usage in the resent years, we have achieved a great deal of processing experience, while the performance of the machine also becomes better. We have 6 sets of this kind of machine (12 m type × 1, 9 m type × 1, 6 m type × 3, 3 m type × 1), which are mainly used in the product manufacturing for famous Chinese companies like Zoomlion, Sany and Sunward, as well as overseas clients. Specifically, the 12 m and 9 m types are mainly used for the telescopic hydraulic cylinder in lorry cranes of Zoomlion, Sany, Sunward.

According to the properties and requirements of the cylinder tube, we choose different boring heads, which come with two types and more than 50 sizes. After years of practical usage, we have accumulated much experience in terms of boring head choosing, parameter setting in accordance with different requirements, materials, and types of workpiece. You are welcome to discuss the production of the CNC skiving and roller burnishing machine with us, so that we can learn from each other and improve together.

Performance and application

Our TZH series CNC skiving and roller burnishing machine are detailed in the tables below. They are mainly used for the bore processing of steel hydraulic cylinder which is made of normal steel pipe and cold drawn pipe. Advanced European skiving and roller burnishing techniques, and domestic cutting tools are used in the machine to achieve skiving and roller burnishing at one stroke. The precision can reach IT8, while the surface roughness can reach Ra0.1-0.4 μm.

About 80%-90% processing time is saved when comparing with traditional skiving and honing techniques. For example, it only takes 5-6 min for the CNC skiving and roller burnishing machine to process a cylinder tube of 180 mm in inner diameter and 4 m in length. However when traditional honing technique is adopted, it will take more than 300 min. Besides, the products processed by our machine can match similar European products in terms of surface roughness and tolerance.

Anti deforming structure are used for the body of the machine, and the parallel rails are made of casting iron. Precision reinforcing rib is used inside the structure.Their toughness is great and stress relieving is achieved by heat aging treatment. So the loading torque of the machine's body is very large, ensuring high productivity and great precision and desirable surface quality. The CNC control system is from Siemens. Proper boring head is adopted, and the working allowance could reach 12mm.

Main parameter

| Item Model | TZH 125X6000 | TZH 250X3000 | TZH 250X6000 | TZH 250X9000 | TZH 360X12000 | |

| Cylinder size | Outer diameter(mm) | Ф73-140 | Ф73-300 | Ф145-426 | ||

| Inner diameter (mm) | Ф63-125 | Ф63-250 | Ф125-350 | |||

| Length (mm) | 1700-6000 | 600-3000 | 1700-6000 | 1700-9000 | 2000-12000 | |

| Mail shaft speed (r/min) | 100-800 | 100-600 | ||||

| Maximum main shaft stroke (mm) | 6350 | 3350 | 69350 | 9350 | 12350 | |

| Main shaft pushing speed (m/min) | 0-2.4 | |||||

| Main shaft power (KW) | 22 | 39 | 51 | 60 | ||

| Total power (KW) | 70 | 106 | 118 | 140 | ||

| Working pressure (Mpa) | 10 | |||||

| CNC system | Siemens 802DSL system | |||||

| Size (length×width×height, m) | 21X4X2 | 15X4.5X2 | 21X4.5X2 | 27X4.5X2 | 34X5X2.2 | |

| Approx. weight (ton) | 35 | 32 | 41 | 50 | 62 | |

Certificate and honor

| Time since invented | Rated annual production capacity | Total production quantity | Certification organization | Honor |

| 4 years | 15 set | 20 set | Product Quality Supervision and Inspection Institute of Wuxi City;China Classification Society | Our products have been identified as high-tech products in Jiangsu province; we gained many patents. |

Links:https://globefindpro.com/products/79009.html

-

Double Action Hydraulic Cylinder

Double Action Hydraulic Cylinder

-

Borescope with LCD Display

Borescope with LCD Display

-

Piston Rod

Piston Rod

-

H-1000 Economical Portable Hardness Tester

H-1000 Economical Portable Hardness Tester

-

Street Washer Hydraulic Cylinder

Street Washer Hydraulic Cylinder

-

CT-2000 Coating Thickness Gauge with External Probe

CT-2000 Coating Thickness Gauge with External Probe

-

Heat Pump Seafood Dryer

Heat Pump Seafood Dryer

-

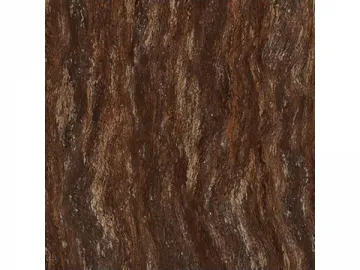

Netturo Polished Porcelain Tiles

Netturo Polished Porcelain Tiles

-

Microwave High Temperature Furnace

Microwave High Temperature Furnace

-

Microwave Vacuum Dryer

Microwave Vacuum Dryer

-

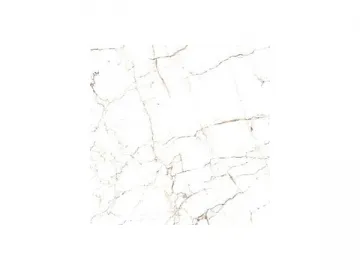

Super White Body Polished and Glazed Porcelain Tile

Super White Body Polished and Glazed Porcelain Tile

-

Mosaic Tiles

Mosaic Tiles