Melt Blown Non Woven Fabric

We use carefully selected FDA approved, all new PP material for the production of the melt blown non woven fabric. As its name indicates, this type of nonwoven textile is manufactured by using melt blowing process, during which the microfiber are directly dispersed into a web and finally bonded by either resin or thermally.

The fabric has a great variety of functions. Following is a list of its advantages when it serves as the raw material for surgical masks.

1. Meltblown nonwovens are typically white colored. They are light in weight and soft in touch. Hence this non-woven material is an optimum raw material solution for surgical masks, and the non-woven surgical masks are always supple, light, and comfortable to wear.

2. Melt blown non woven fabric has uniform texture as well as great breathability and air permeability. Thus, meltblown non-woven masks won't make wearers feel suffocated.

3. This type of engineered fabric features good physical property, that is, high tear strength. Therefore, it is easy and convenient for processing, which reduces the mask production cost accordingly.

4. Without small fiber particles on surface, this material also has good dust filtration and bacterial barrier property.

Steps while using meltblown non-woven fabric for mask production

1.Slit the jumbo MB nonwoven fabric rolls into smaller ones.

2.Use mask making machines and spot welding machines for mask production.

While acting as the raw material for surgical masks, our can also be used as filter media for other fine particle filtration purposes.

Our meltblown non woven fabrics have found export destinations in Japan, Europe, Southeast Asia, and many other countries and regions. While delivering, we will include the Product Test Report to make customers feel rest assured.

Links:https://globefindpro.com/products/79856.html

-

Spunbond Non Woven Fabric

Spunbond Non Woven Fabric

-

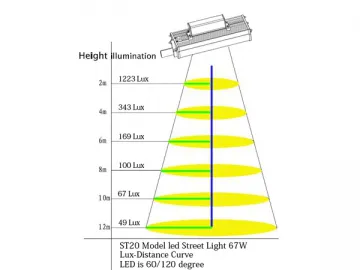

ST-20-67W LED Street Light

ST-20-67W LED Street Light

-

LED Bulb with IR Motion Sensor

LED Bulb with IR Motion Sensor

-

ST-27-E40/60W LED Street Light

ST-27-E40/60W LED Street Light

-

XH03-20 Block Making Machine

XH03-20 Block Making Machine

-

XH04-20 Block Making Machine

XH04-20 Block Making Machine

-

PVC Pallet

PVC Pallet

-

TC-ST20UB35W600A3-W LED Street Light

TC-ST20UB35W600A3-W LED Street Light

-

QT-20-28W LED Flood Light

QT-20-28W LED Flood Light

-

LED Ceiling Light

LED Ceiling Light

-

SMMS Non Woven Fabric

SMMS Non Woven Fabric

-

TC-ST20UB50W800A3-W LED Street Light

TC-ST20UB50W800A3-W LED Street Light