XH03-20 Block Making Machine

PLC control panel

Advantage

1. Multifunction

Through the replacement of moulds, the XH03-20 block making machine can manufacture different blocks, such as the hollow block, solid brick, paver and so on.

2. Fast Speed

With the help of a high-powered hydraulic pump, the mould is pressed and lifted quickly. The block making machine may pour concrete into a mould and prepare concrete at the same time.

3. Automation

The block making machine adopts an intelligent PLC control system that has been loaded with the program control and automatic diagnostic program, so as to realize automatic operation.

4. High Quality

The switches and power supply of the block making machine are purchased from brand-name enterprises. Moulds have undergone carburizing heat treatment.

5. Labor Saving

The produced bricks can be stacked automatically after moulding, which helps to save labor force.

Hydraulic station PLC Products sample

Technical Parameters

| Dimension | 8000×6000×2500mm |

| Rated pressure | 10MPa |

| Vibration | Table vibration |

| Vibration frequency | 2800-4500r/min |

| Pallet size | 680×530mm |

| Cycle time | 15-20s |

| Power | 18kw |

| Weight | 3700kg |

Quantity of Produced Blocks

| Block name | Dimension (L×W×H) | PCS/cycle | PCS/hour | PCS/day (8 hours) | PCS/year (300 days) |

| Hollow blocks | 390×190×190mm | 3 | 540 | 4320 | 1296000 |

| Perforated blocks | 240×115×90mm | 10 | 1800 | 14400 | 4320000 |

| Solid bricks | 240×115×50mm | 20 | 3600 | 28800 | 8640000 |

| Color bricks | 200×100×60mm | 12 | 2160 | 17280 | 5184000 |

Related Names

Building Material Making Machinery | Engineering Equipment | Brick Machine Supplier

Links:https://globefindpro.com/products/79861.html

-

XH04-20 Block Making Machine

XH04-20 Block Making Machine

-

PL Series Concrete Batching Plant

PL Series Concrete Batching Plant

-

MBD-65W Dimmable LED Panel Light

MBD-65W Dimmable LED Panel Light

-

Wooden Pallet

Wooden Pallet

-

XH08-15 Block Making Machine

XH08-15 Block Making Machine

-

ST-66-57W LED Street Light

ST-66-57W LED Street Light

-

ST-27-E40/60W LED Street Light

ST-27-E40/60W LED Street Light

-

LED Bulb with IR Motion Sensor

LED Bulb with IR Motion Sensor

-

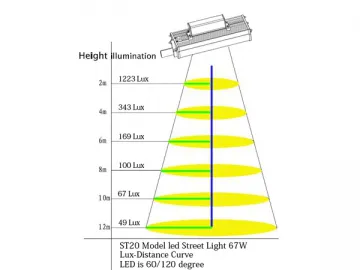

ST-20-67W LED Street Light

ST-20-67W LED Street Light

-

Spunbond Non Woven Fabric

Spunbond Non Woven Fabric

-

Melt Blown Non Woven Fabric

Melt Blown Non Woven Fabric

-

PVC Pallet

PVC Pallet