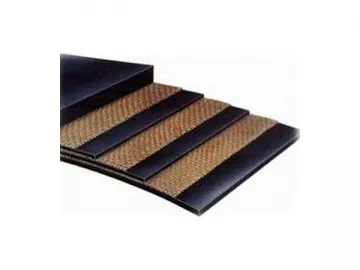

EP Conveyor Belt

1. Structure

The EP conveyor belt system applies canvas woven by polyester in warp and polyamide in weft. Its carcass is made of NN canvas that is nylon woven. This conveyer belt is used to long distance transportation with such conditions as big impact and severe abrasion.

2. Features

The fabric conveyor belt is characterized by high modulus, light weight, good troughability, low elongation, and high strength.

Note: Number of canvas layers should be no more than 5 for preventing possible crease.

3. Description

Our EP conveyor belt adopts polyester canvas with characteristics as flexibility and good shock absorption. When using, its low elongation at the specified load helps shorten the derived stroke, thereby lowering the belt conveyor cost. Also for that reason, the multiply fabric reinforced rubber conveyor belt is fit for long-distance conveying.

When this conveyor belt is used in the humid environment, its rubber belt strength and bonding strength will never be weakened. In other words, our conveyor belting can be used for a long time. Being perfectly resistant to heat, abrasion, and impact, it is appropriate for medium-long distance conveying heavy-load materials at a high speed.

The polyester conveyor belt can speed up the conveying speed while reducing the transmission power. In addition, it reduces the pulley diameter. Typically utilized as food conveyor belt and coal conveyor belt, this range of product is also applicable for industries such as mines, power generation, and building materials.

4. Specifications of EP Conveyor Belt

| Fabric | Fabric Structure | Fabric Code | Fabric Layers | Thickness of Covering Layer | ||

| Warp | Weft | Upper Layer | Lower Layer | |||

| Polyester Canvas | Polyester | Polyester | EP100 | 3-9 | ||

| EP150 | ||||||

| EP200 | ||||||

| EP250 | ||||||

| EP300 | 3-6 | |||||

| EP400 | ||||||

| EP500 | 3-5 | |||||

| EP600 | ||||||

5. Performance of EP Conveyor Belt

5.1 Rubber Layer

| Item | Performance Index | |||

| H | D | L | ||

| Tensile Strength | Mpa≥ | 24 | 18 | 15 |

| Elongation at Break | %≥ | 450 | 400 | 350 |

| Abrasion | mm3≤ | 120 | 100 | 200 |

5.2 Adhesive Strength

| Item | Between Fabric Layers | ||

| Thickness of Rubber Layer | Thickness of Rubber Layer>1.5mm | ||

| Average Value of All Samples | 405 | 3.2 | 3.5 |

| Minimum Value among All Samples | 3.9 | 2.4 | 2.9 |

Links:https://globefindpro.com/products/80387.html

-

SCANIA Revolving Wheel Nut (DX0045)

SCANIA Revolving Wheel Nut (DX0045)

-

SCANIA Rear Wheel Bolt (DXE018)

SCANIA Rear Wheel Bolt (DXE018)

-

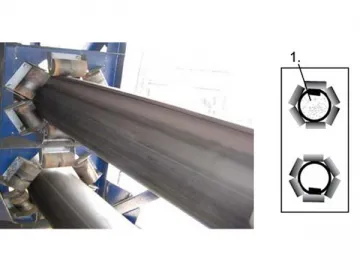

Pipe Conveyor Belt

Pipe Conveyor Belt

-

Spring Pin 25X110

Spring Pin 25X110

-

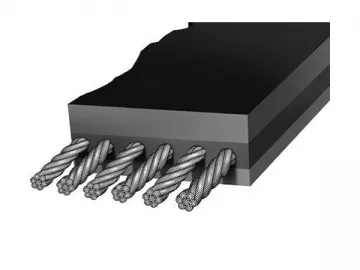

Standard Steel Cord Conveyor Belt

Standard Steel Cord Conveyor Belt

-

Heat Resistant Conveyor Belt

Heat Resistant Conveyor Belt

-

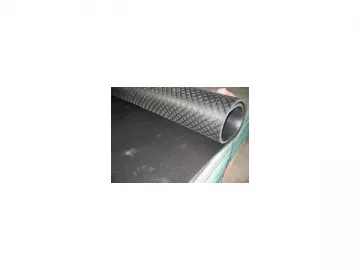

Livestock Rubber Matting

Livestock Rubber Matting

-

VOLVO Front Wheel Bolt (DXE026)

VOLVO Front Wheel Bolt (DXE026)

-

DODGE Spring Pin (DX0064)

DODGE Spring Pin (DX0064)

-

HYUNDAI 3.5Ton Rear Wheel Bolt (DXK019)

HYUNDAI 3.5Ton Rear Wheel Bolt (DXK019)

-

VOLVO Torque Rod Bush (DXT013)

VOLVO Torque Rod Bush (DXT013)

-

Segment Bolt M22 (DXE068)

Segment Bolt M22 (DXE068)