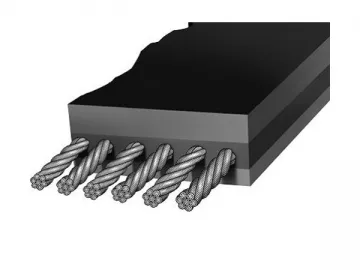

Standard Steel Cord Conveyor Belt

The standard steel cord conveyor belt uses high strength steel wire rope as the carcass materials. The steel wire rope, after cold rolling as well as having been added with core rubber and rubber layer, is treated with vulcanization process to form standard steel cord belt used for conveying. Zinc coated steel wire rope meets various special requirements. It comes with high flexibility but low elongation, and can tightly bonded with core rubber to form anti-corrosion protective layer.

Applications of Steel Cord Conveyor Belt

As a kind of rubber conveyor belting with steel wire reinforcement, the steel cord conveyor belt is suited to materials conveying in the industries including coal, mines, ports, electric power, metallurgy, construction materials, etc.

Hence, if you are searching for durable coal conveyor belts, mining conveyor belts, etc., then this range of conveyor belting with steel cord reinforcement is the optimum choice for you. It is designed to handle the toughest conveying applications.

Features and Advantages of Steel Cord Conveyor Belt

1. High Strength Steel Wire Rope

Our steel wire reinforced rubber conveyor belt meet many different clients' requirements. We continuously develop higher strength steel cord conveyor belt for long-distance conveying system. The tensile strength range is from 630N/mm-5400N/mm.

2. Less Strokes of Tension

On the premise of rated tensile force, our steel cord belt has the maximum elongation of 0.25%. It can decrease the fees of tensioning systems in many application occasions. Consequently, it is the best belting solution for long distance transportation or conveying occasions of low elongation.

3. Longer Joint Lifespan

Dynamic coupling of our steel cord conveyor belt has been inspected by a testing machine. When its dynamic coupling withstands load that exceeds 50% of the rated strength, the joint if it tested in compliance with DIN22131-3, still has the service life as long as that of belt.

4. High Impact Resistance

The rubber layer and core rubber are closely bonded, offering better resistance to impact and tearing.

5. Lower Transportation Cost

The standard steel cord conveyor belt needs just a few joints, shorter tensioning stroke, etc. All those helps lower the investment. Its longer service life means short downtime, lowering unit transportation cost.

Width: 800mm-2000mm

| Model | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

| Longitudinal Tensile Strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Maximum Nominal Diameter of Steel Wire Rope (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Spacing Between Steel Wire Ropes(mm) | 10 ±1.5 | 10 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 12 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 15 ±1.5 | 16 ±1.5 | 17 ±1.5 | 17 ±1.5 |

| Thickness of Upper Covering Layer(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Thickness of Lower Covering Layer(mm) | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8.5 | 9 |

| Width (mm) | No. of Steel Wire Rope | ||||||||||||

| ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | |

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | ||

| Remark 1. As a conveyer belt specialist, we are able to customize covering layer thickness, steel wire rope diameter, and space between steel wire ropes. 2. We can produce our steel cord conveyor belts according to German DIN22131 standard, Australia AS133,and Japanese JISK6369 standard. | |||||||||||||

1. Rubber Performance

| Item | Performance Index | |||

| H | D | L | ||

| Tensile Strength | Mpa≥ | 24.0 | 18.0 | 15.0 |

| Elongation at Break | %≥ | 450 | 400 | 350 |

| Abrasion Loss | mm3≤ | 120 | 100 | 200 |

2. Bonding Strength between Layers

| Model | Bonding Strength of Steel Wire Rope | |

| Before Aging | After Aging | |

| ST630 | 60 | 55 |

| ST800 | 70 | 65 |

| ST1000 | 80 | 75 |

| ST1250 | 95 | 90 |

| ST1600 | 105 | 95 |

| ST2000 | 105 | 95 |

| ST2500 | 130 | 120 |

| ST2150 | 140 | 130 |

| ST3500 | 145 | 140 |

| ST4000 | 150 | 145 |

| ST4500 | 165 | 160 |

| ST5000 | 175 | 170 |

| ST5400 | 180 | 175 |

Links:https://globefindpro.com/products/80393.html

-

Heat Resistant Conveyor Belt

Heat Resistant Conveyor Belt

-

SCANIA Front Wheel Bolt (DXE017)

SCANIA Front Wheel Bolt (DXE017)

-

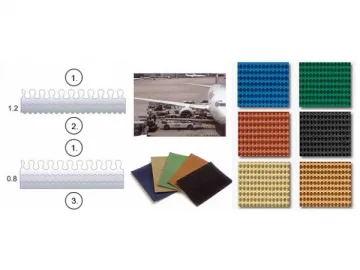

Rough Top Conveyor Belt

Rough Top Conveyor Belt

-

Cold Resistant Conveyor Belt

Cold Resistant Conveyor Belt

-

Sidewall Conveyor Belt

Sidewall Conveyor Belt

-

Advanced Rubber Sheet

Advanced Rubber Sheet

-

Spring Pin 25X110

Spring Pin 25X110

-

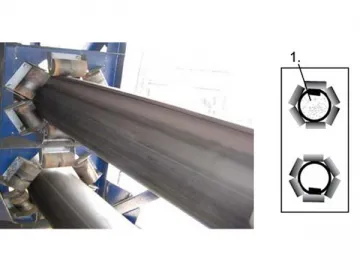

Pipe Conveyor Belt

Pipe Conveyor Belt

-

SCANIA Rear Wheel Bolt (DXE018)

SCANIA Rear Wheel Bolt (DXE018)

-

SCANIA Revolving Wheel Nut (DX0045)

SCANIA Revolving Wheel Nut (DX0045)

-

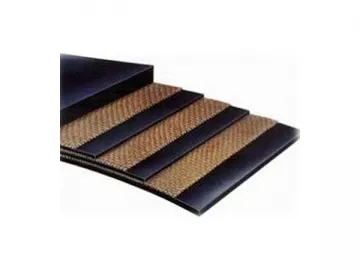

EP Conveyor Belt

EP Conveyor Belt

-

Livestock Rubber Matting

Livestock Rubber Matting