CK130 CNC Pipe Threading Lathe Machine

Features

1. The CK130 CNC pipe threading lathe machine utilizes the tapered roller bearing to ensure the spindle having sufficient rigidity.

2. The spindle of the product is fabricated with large bore diameter. It is configured with the front and rear double chucks.

3. The machine bed slide way has high durability and wear resistance via the processing of supersonic frequency hardening. The saddle slide way adopts the structure of inlaying wear-resisting material to avoid the stick-slip motion.

4. The spindle of the CNC pipe threading lathe machine employs the 33.3HZ low frequency large torque servo motor with stepless speed changing.

5. The product is fitted with the automatic lubricating system facilitating the maintenance.

6. The CNC system can be compliant with the requirements of the users.

Application Range

The product is the special machine tool for the industries involving oil drilling, geology and metallurgy to process diversified pipes and pipe threads. It can implement pipe thread processing, and lathe the metric and inch thread of circular cylinder and taper pipe.

Manufacturing Equipment

The CNC pipe threading lathe machine manufacturing process needs to use the slideway grinding machine, supersonic frequency induction hardening machine tool, gantry planing machine, gantry milling machine, CNC boring machine, etc.

| Item | Unit | Data |

| Max. Rotation Diameter | mm | 610 |

| Max. Turning Length (Max. Machining Length) | mm | 1000 |

| Max. Machinable Pipe External Diameter | mm | 133 |

| Spindle Bore Diameter | mm | 140 |

| Number of Spindle Speeds | Main Servo Stepless Speed Changing, 10-800rpm | |

| Feed Servo Motor Torque X/Z | N.m | 4/6 |

| Chuck Type | Ordinary Front and Rear Three-jaw Chuck 400mm | |

| Toolpost Type | 191×191 or 200×200 Four-station Vertical Toolpost | |

| Rapid Traverse Speed X/Z | m/min | 4/4 |

| Tailstock Barrel Diameter | mm | 75 |

| Tailstock Barrel Stroke | mm | 150 |

| Tailstock Center Barrel Taper | Morse No. 5 | |

| Tailstock Center Taper | Morse No. 5 | |

| Height of Spindle Center to Slide Way | mm | 305 |

| Main Electric Motor | Spindle Servo Motor 50HZ 11kW 3000r/min | |

| Weight | kg | 2600 |

| Overall Dimension (L×W×H) | mm | 2650×1450×1700 |

| CNC System | mm | Beijing KND100Ti / GSK980TA2 (Optional) |

Related Names

Pipe Processing Machine | CNC Machining Tool | Computerized Lathe

Links:https://globefindpro.com/products/81292.html

-

Waterproof Dimmable LED Driver

Waterproof Dimmable LED Driver

-

HZ-130Y Water Well Drilling Rig

HZ-130Y Water Well Drilling Rig

-

24W 12/24V LED Driver

24W 12/24V LED Driver

-

35W-150W Built-in LED Driver

35W-150W Built-in LED Driver

-

BW-250 Mud Pump

BW-250 Mud Pump

-

QY-200 Multifunction Water Well Drilling Rig

QY-200 Multifunction Water Well Drilling Rig

-

HZ-200YY Water Well Drilling Rig

HZ-200YY Water Well Drilling Rig

-

36W 12-48V LED Driver

36W 12-48V LED Driver

-

XYC-3 Truck-Mounted Water Well Drilling Rig

XYC-3 Truck-Mounted Water Well Drilling Rig

-

QK1322 CNC Pipe Threading Lathe Machine

QK1322 CNC Pipe Threading Lathe Machine

-

25W-100W Waterproof LED Driver

25W-100W Waterproof LED Driver

-

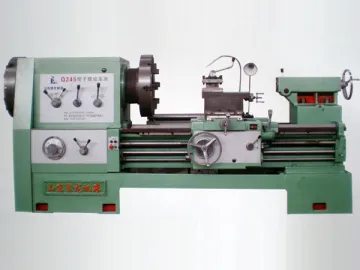

Q245 Pipe Threading Lathe Machine

Q245 Pipe Threading Lathe Machine