XY-44A Core Drilling Rig

Features

1. The XY-44A core drilling rig is fabricated with reasonable speed range, 8 speed levels, and large torque at low speed which can be up to 8000N.m. It is not only suitable for alloy and diamond core drilling, but also applied for engineering geological investigation, hydrological well drilling, and the construction of pile foundation engineering.

2. The spindle bore diameter is as large as 93mm. Featuring biaxial cylinder hydraulic feeding, long stroke of up to 600mm, and strong technological adaptability, the spindle of the product is very fit for large diameter drilling rod wireline coring (upper part coring) drilling, and is conducive to the enhancement of the drilling efficiency and the reduction of the drilling accident in the hole.

3. The core drilling rig has large drilling capacity. The rated drilling depth of the wireline coring drilling rod with the diameter of 71mm can be up to 1000m.

4. The product is also highlighted by good dismountability and light weight with the net weight of only 2300kg. The main body of the machine can be dismantled into 10 major parts. The maximum detachable part weighs 300kg. Based on that, the machine is particularly applicable for working in the mountain area.

5. The hydraulic chuck of the core drilling rig uses one-way oil supply. It has large chucking power and chucks the drilling rod stably.

6. The product is configured with the hydromatic brake. It is capable of deep well drilling with stable and safe process for the drilling tool into the well.

7. The machine adopts single gear oil pump to implement oil supply. The installation is simple and it is very convenient to use the device. Moreover, the power consumption is low. The hydraulic system works stably with low oil temperature. In addition, the hand-operated oil pump is available. When the power machine fails to work, the operator can use the hand-operated oil pump to take the drilling tools out of the hole.

8. The core drilling rig has compact structure and reasonable layout with all the parts exposed to the outside and no overlapping with each other. The maintenance and repair work can be conducted easily.

9. The machine has low center of gravity, long backward travel of up to 460mm, and good high speed drilling stability. It can be fixed firmly.

10. The product is also fitted with shockproof instrument which has long service lifetime and facilitates mastering the condition in the hole. Designed with not too many control handles, it is flexible and reliable to operate.

11. The core drilling rig has high degree of universal property. Its 60% parts can be applicable for the XY-4 product. As to the XY-42 product, the proportion of the interchangeable parts of the product is as high as 75%.

Technical Parameters

1. Drilling Capacity

A. Core Drilling

| Type of Drilling Rod | Specification of the Drilling Rod (mm) | Drilling Depth (m) | |

| Domestic Drilling Rod | Inside and Outside Flat Type Drilling Rod | Φ43×6 | 1400 |

| Φ54×6 | 1000 | ||

| Φ67×6 | 830 | ||

| Φ50×5.5 | 1300 | ||

| Φ60×6 | 950 | ||

| Φ55.5×4.75 | 1400 | ||

| Φ71×5 | 1000 | ||

| Φ89×5 | 800 | ||

| DCDMA (Diamond Core Drilling Manufacturers Association) Drilling Rod | Internally Upset Drilling Rod | BW | 1250 |

| NW | 1000 | ||

| HW | 660 | ||

| Wireline Coring Drilling Rod | BQ | 1400 | |

| NQ | 1100 | ||

| HQ | 750 | ||

| Specification of the Drilling Rod (mm) | Drilling Diameter (mm) | Drilling Depth (m) |

| Φ 60 Externally Upset Type | 200 | 800 |

| Φ73 Externally Upset Type | 350 | 500 |

| Φ89 Externally Upset Type | 500 | 300 |

| Specification of the Drilling Rod (mm) | Drilling Diameter (mm) | Drilling Depth (m) |

| Φ 89 Externally Upset Type | 1000 (Unconsolidated Formation) | 100 |

| 600 (Hard Rock Formation) |

2. Gyrator (Gyration Angle: 0° -360°)

A. Type: Double Hydraulic Cylinders Hydraulic Feeding Mechanical Gyration Type

B. Spindle Bore Diameter:93mm

C. Spindle Speed (r/min)

| Power Machine Speed | 1480 (Electric Motor) | 1800 (Diesel Engine) |

| Low Forward Speed | 50, 80, 139, 227, 316, 401 | 60, 90, 166, 272, 379, 481 |

| High Forward Speed | 153, 247, 429, 696, 970, 1230 | 183, 296, 514, 835, 1164, 1476 |

| Reverse Speed | 53, 165 | 63, 198 |

D. Max. Torque of Spindle: 8000N.m

E. Max. Pressure Capacity of Spindle: 90kN

F. Spindle Stroke: 600mm

G. Max. Lifting Capacity of Spindle: 120kN

3. Winch

A. Type: Planetary Gear Transmission, Handle Brake

B. Wire Rope Diameter: 18.5mm

C. Max. Lifting Capacity of Single Rope: 45kN

D. Wire Rope Lifting Speed (1480r/min of Power Machine): 0.7, 1.29, 1.84, 2.68m/s

4. Clutch and Transmission System

A. Type of Clutch: Normally Closed Single Disc Dry Friction Clutch (Matching with 6T46 Gearbox)

B. Gearbox: WLY6T46 Automobile Transmission Assembly with 6 Forward Gears and 1 Reverse Gear (Manufacturer: Zhejiang Wanliyang Transmission Co., ltd.)

5. Body Frame

Type: Skid Type with Sliding Underframe

6. Oil Pump

A. Type: Single Gear Oil Pump

B. Displacement: 20ml

C. Max. Pressure: 25MPa

D. Working Pressure: 20MPa

7. Power

| Power Type | Electric Motor | Diesel Engine |

| Model | Y225S-4 | YC4E135-21 |

| Power | 37kW | 103kW |

| Speed | 1480r/min | 2800r/min |

8. Hydromatic Brake

A. Working Speed: 700-1800r/min

B. Single Rope Balance Speed: 3-8m/s

C. Single Rope Balance Load: 45kN

9. Weight of Main Body: 2300kg

10. Main Dimension

A. Overall Dimension (L×W×H): 3050×1100×1920mm

B. Backward Travel: 460mm

Related Names

Percussion Drill Rig | Borehole Drilling Equipment | Geological Exploration Machine

Links:https://globefindpro.com/products/81310.html

-

HZ-200GT Water Well Drilling Rig

HZ-200GT Water Well Drilling Rig

-

BW-200 Mud Pump

BW-200 Mud Pump

-

Manual/Semi-Automatic Pipe Cutting Circular Saw

Manual/Semi-Automatic Pipe Cutting Circular Saw

-

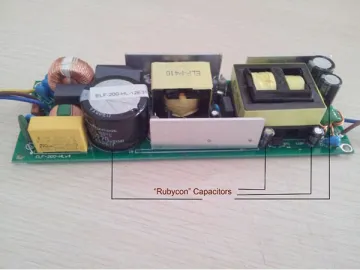

190W-220W Waterproof LED Driver

190W-220W Waterproof LED Driver

-

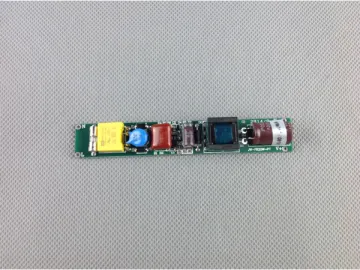

Non-Isolated LED Driver

Non-Isolated LED Driver

-

Q43-3150 Hydraulic Alligator Shear

Q43-3150 Hydraulic Alligator Shear

-

35W-150W Waterproof LED Driver

35W-150W Waterproof LED Driver

-

Q1322 Pipe Threading Lathe Machine

Q1322 Pipe Threading Lathe Machine

-

XY-44B Intelligent Electric-Control Drilling Rig

XY-44B Intelligent Electric-Control Drilling Rig

-

XYX-2 Trailer-Mounted Water Well Drilling Rig

XYX-2 Trailer-Mounted Water Well Drilling Rig

-

5W-12W Built-in LED Driver

5W-12W Built-in LED Driver

-

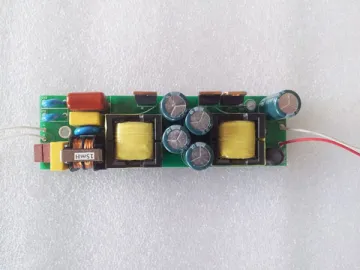

25W-100W Built-in LED Driver

25W-100W Built-in LED Driver