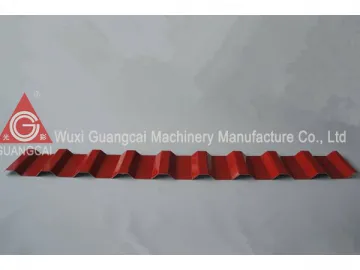

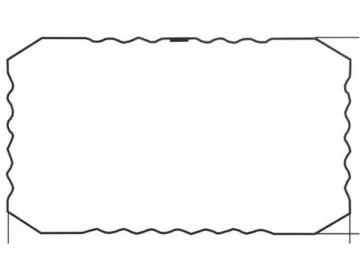

GWC25-205-820 Roof Panel Roll Forming Machine

Roof panels made by this GWC25-205-820 roof panel roll forming machine are extremely popular on the market because of the high utilization rate, low depth (the height from the top of a crest to the bottom of a trough) and the cost-effective performance.

Aside from the common features shared by this series, our product has some unique properties as listed below.

Advantages

1. This is a dual-use machine because one pitch could be added, making it into GWC25-205-1025 type and the feeding width is adjusted to 1200mm.

2. This roof panel roll forming machine is a very mature product, and there is no need to redesign it, thereby greatly reducing the production cycle.

Processing Flow

Passive decoiling → guided material feeding → rolling → cut-to-length → offloading

Composition

1. 5T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Model | GWC25-205-820/1025 | Reference |

| Applicable material | Color plate, galvanized sheet, galvalume plate and aluminum sheet | This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width | 1000/1200mm | |

| Processing thickness | 0.3-0.8mm | |

| Roller material | 45# steel coated with hard chrome | |

| Main motor power / hydraulic station power | 3kW / 3kW | These parameters can be set according to the required production capacity. |

| Forming passes | 18 | |

| Forming speed | 5-15 meters/minute | |

| Machine dimensions | 9.5×1.3×1.2m | |

| Machine weight | 7T |

Related Names

Metal Sheet Roofing Forming Equipment | Steel Roofing Sheet Roll Former | Residential Metal Roof Making Machine

Links:https://globefindpro.com/products/81417.html

-

Folding and Roll Forming Machine

Folding and Roll Forming Machine

-

GWC C Purlin/Z Purlin Roll Forming Machine

GWC C Purlin/Z Purlin Roll Forming Machine

-

Guardrail Roll Forming Machine

Guardrail Roll Forming Machine

-

GWC55-220-880 Glazed Roof Tile Roll Forming Machine

GWC55-220-880 Glazed Roof Tile Roll Forming Machine

-

Ceiling Panel

Ceiling Panel

-

Roof Panel

Roof Panel

-

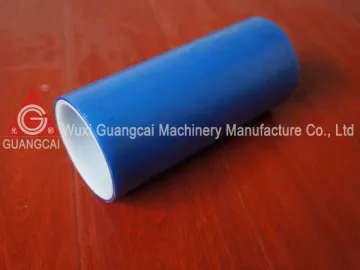

PE Blue Protection Film

PE Blue Protection Film

-

Down Pipe Roll Forming Machine

Down Pipe Roll Forming Machine

-

PET High Temperature Protection Film

PET High Temperature Protection Film

-

Rain Gutter Roll Forming Machine

Rain Gutter Roll Forming Machine

-

Down Pipe

Down Pipe

-

GWC100-300 Z Purlin Roll Forming Machine

GWC100-300 Z Purlin Roll Forming Machine