Horizontal Machining Center

Features

1. The horizontal machining center possesses splendid cutting performance with high efficiency, high accuracy and high stiffness.

2. The rectangular quenched slideways are equipped in X, Y and Z directions, the hardness of which reaches over HRC52. The excellent stiffness and vibration resistance lay solid foundations for heavy-duty cutting and high-precision processing.

3. This product adopts the gear box with large torque. The spindle motor performs with two-stage gearing and automatically switches between two gearing modes. The speed change of each gearing mode is stepless, which largely increases the torque of low speed operation.

4. The high-precision operating platform performs positioning via 4 sets of highly precise conical pins and grooves. This well ensures the accuracy and stability of platform for long-term working.

5. The meshing of tooth coupling with large diameter guarantees exact scale division and positioning.

6. This horizontal machining center is configured with grating position detection systems in X, Y and Z directions. Besides, the full-closed loop control is realized.

Standard Attachments

1 set of leveling bolts

1 set of water cooling system

1 set of automatic chip cleaner

1 set of spindle oil cooling system

Optional Configurations

1 set of continuous indexing table (division value: 0.001°) (oil-water separation)

1 set of pneumatic system (excluding the air pump)

Technical Parameters

| Item | HMC163 |

| Maximum travel in X axis (from left to right of operating platform) | 950mm |

| Maximum travel in Y axis (from top to bottom of spindle) | 820mm |

| Maximum travel in Z axis (from front to back of stand column) | 750mm |

| Distance from top end face of operating platform to spindle center | 0-820mm |

| Distance from operating platform center to spindled end face | 200-950mm |

| Size of operating platform | 630×630mm |

| Maximum loading capacity of operating platform | 1200kg |

| Facing of operating platform | 24-M16 screw thread |

| Minimum indexing angle of operating platform | 1° (Option: 0.001°) |

| Spindle speed | 50-5000rpm |

| Gear shift of spindle | 2 ranges |

| Taper hole of spindle | 7/24, BT50 |

| Bearing hole diameter of spindle | Ø100mm |

| Fast feed speed | 24m/min. |

| Feed speed for cutting | 1-12000mm/min. |

| Positioning accuracy (full stroke) | ±5μm |

| Repositioning accuracy | ±2.5μm |

| Tool bar mode | BT-50 |

| Tool magazine capacity | 60 |

| Maximum diameter of tool | Ø115 (Ø270)mm |

| Maximum length of tool | 410mm |

| Maximum weight of tool | 25kg |

| Tool selection mode | Optional |

| Random address fixing system | |

| Time of tool changing | 6s |

| Numbers of operating platform | 2 |

| APC switching time | 16s |

| Spindle motor (30min./continuous) | 18.5/22KW |

| Feed motor | X/Z22Nm, Y30Nm |

| Power of cooling motor | 0.37KW×2 |

| Hydraulic motor | 2.2KW |

| Power supply | AC380V ±10, 50/60 ±1Hz, 72 KVA |

| Air supple | 0.5-0.8MPa |

| Oil groove capacity for cutting | 400L |

| Floor area | 3300×4800mm |

| Weight | 18500kg |

| Numerical control system | Fanuc |

Related Names

Heavy Duty Machine Tool | Metal Milling Machine | High Speed Machining Equipment

Links:https://globefindpro.com/products/81495.html

-

CNC Pipe Push Bending Machine

CNC Pipe Push Bending Machine

-

Carbon Steel 90 Degree Long Radius Elbow

Carbon Steel 90 Degree Long Radius Elbow

-

Carbon Steel 180 Degree Short Radius Elbow

Carbon Steel 180 Degree Short Radius Elbow

-

Paper Bag with Aluminium Foil Inside

Paper Bag with Aluminium Foil Inside

-

Carbon Steel 180 Degree Long Radius Elbow

Carbon Steel 180 Degree Long Radius Elbow

-

Carbon Steel Flange

Carbon Steel Flange

-

PE Milk White Protection Film

PE Milk White Protection Film

-

Carbon Steel 45 Degree Short Radius Elbow

Carbon Steel 45 Degree Short Radius Elbow

-

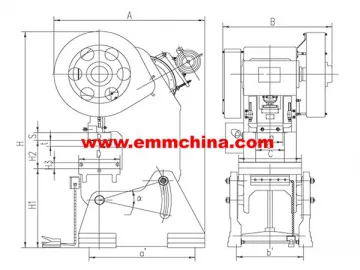

EMH23 Series C-frame High Performance Inclinable Presses

EMH23 Series C-frame High Performance Inclinable Presses

-

Patented Automatic Steel Grinding Ball Production Line

Patented Automatic Steel Grinding Ball Production Line

-

Carbon Steel Pipe Cap

Carbon Steel Pipe Cap

-

PE Transparent Protection Film

PE Transparent Protection Film