Steel Coil Pickling Shearing

After being sheared and processed, our pickled steel plate is mainly distributed to the automobile manufacturer as the plate for vehicle chassis.

Pickling Cut-to-length Processing Flow

Uncoiling --- Stretching-bending Rectifying --- Cleaning --- Shearing --- Inspection --- Packaging

1. Uncoiling: Remove the package of the steel coil. Utilize the crane to lift the steel coil and put it onto the shearing equipment.

2. Stretching-bending Rectifying: Rectifying the steel plate position to guarantee the accuracy of the steel plate before shearing. That is for making sure the shearing precision.

3. Cleaning: Clean off the dust or other contaminants on the surface of steel plate.

4. Shearing: Shear the steel plate with the size conforming to the requirements of customers.

5. Inspection: The quality control personnel make surface quality checking to the sheared steel plate.

6. Packaging: Package the processed steel plate according to the quantity or weight that the customers require.

Specification of Pickling Cut-to-length Line

| Processing Material | Pickling Steel Coil |

| Thickness of Material | 1.5 mm ~6.0 mm |

| Width of Material | 600mm ~1650 mm |

| Length of Shearing | 500mm ~6000 mm |

| Length Tolerance | ± 0.8 mm |

| Max. Shear Strength | 560 N/mm |

| Max. Yield Strength | 420 N/mm |

| Max. Production Line Speed | 70 m/min |

| Outside Diameter of Steel Coil | < 2000 mm |

| Inside Diameter of Steel Coil | 508mm / 610 mm |

| Processing Capacity | 70,000 MT/year |

We are a professional steel products and related service supplier. Welcome customers to consult our products.

Related Names

Steel Pickling Process Equipment | Metal Cutting Service | Sheet Metal Shearing Machine

Links:https://globefindpro.com/products/81729.html

-

Q Series European Style Switch and Socket

Q Series European Style Switch and Socket

-

M Series European Style Switch and Socket

M Series European Style Switch and Socket

-

Exhaust Fan

Exhaust Fan

-

4 Gang 1 Way Switch

4 Gang 1 Way Switch

-

WD Series Switch and Socket

WD Series Switch and Socket

-

MA Series European Style Switch and Socket

MA Series European Style Switch and Socket

-

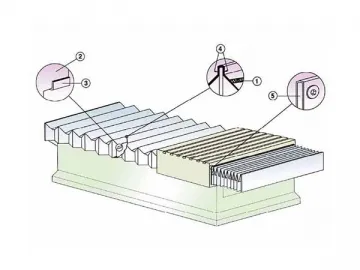

High Frequency Welded Bellow Covers

High Frequency Welded Bellow Covers

-

TLG Series Steel Cable Drag Chains with Stainless Steel Straps

TLG Series Steel Cable Drag Chains with Stainless Steel Straps

-

Universal Bellow Covers

Universal Bellow Covers

-

Thermit Welding Bellow Covers for Linear Slides

Thermit Welding Bellow Covers for Linear Slides

-

Y Series British Style Switch and Socket

Y Series British Style Switch and Socket

-

TEZ(F) Series Assembling Composite Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

TEZ(F) Series Assembling Composite Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains