Automatic Piping Welding Workstation (Type-D)

Model: PAWWS-16Aa/24Aa

Technical Parameters Pipe Diameter Applicable: DN400/DN600 Pipe Wall Thickness Applicable: 3-20/3-20/3-20/10-60MM Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel Welding Line Applicable: Various of butt welding lines for pipe spools such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc. Welding Procedure: FCAW/FCAW/FCAW/SAW (Option or as per request) Welding Power: NBC-500/NBC-500/NBC-500/MZ-630 (Option or as per request)Applications

The automatic piping welding workstation is used for projects with a majority of standard wall thickness pipes and few heavy wall thickness pipes. It can also be used for projects with a majority of heavy wall thickness pipes and few standard wall thickness pipes (PAWWS-24Dd).

Scan QR to Read

Links:https://globefindpro.com/products/8216.html

Links:https://globefindpro.com/products/8216.html

Recommended Products

-

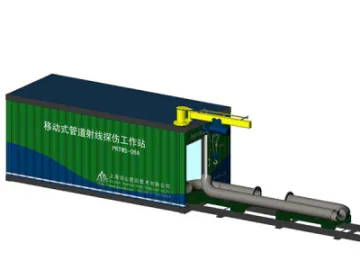

Piping Radiographic Test Work Station (Type-A)

Piping Radiographic Test Work Station (Type-A)

-

Pipe Automatic Welding Machine (FCAW/GMAW)

Pipe Automatic Welding Machine (FCAW/GMAW)

-

Numerical Control Pipe Cutting Band Saw Machine

Numerical Control Pipe Cutting Band Saw Machine

-

Split Type Automatic Pipe Welding Machine (Ordinary Type)

Split Type Automatic Pipe Welding Machine (Ordinary Type)

-

Orbital Automatic Pipeline Welding Machine (FCAW/GMAW)

Orbital Automatic Pipeline Welding Machine (FCAW/GMAW)

-

Transverse Pipe Automatic Conveying System

Transverse Pipe Automatic Conveying System

-

High Speed Pipe Cutting Band Saw Machine

High Speed Pipe Cutting Band Saw Machine

-

Automatic Pipe Welding Machine (SAW)

Automatic Pipe Welding Machine (SAW)

-

Pipe Fabrication Production Line (Numerical Control Type)

Pipe Fabrication Production Line (Numerical Control Type)

-

Orbital Automatic Pipe Welding Machine (GTAW/TIG)

Orbital Automatic Pipe Welding Machine (GTAW/TIG)

-

Welding Elbow Automatic Welding Machine (FCAW/GMAW)

Welding Elbow Automatic Welding Machine (FCAW/GMAW)

-

Automatic Pipe Welding Machine (GTAW)

Automatic Pipe Welding Machine (GTAW)

Hot Products