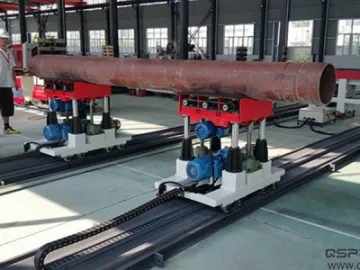

Transverse Pipe Automatic Conveying System

Model: PLTCS-16Aa/24Aa; PLTCS -16Bb/24Bb/32Bb/40Bb

Scan QR to Read

Links:https://globefindpro.com/products/8222.html

Links:https://globefindpro.com/products/8222.html

Recommended Products

-

Longitudinal Pipe Automatic Conveying System

Longitudinal Pipe Automatic Conveying System

-

Split Type Automatic Pipe Welding Machine (Heavy Duty Type)

Split Type Automatic Pipe Welding Machine (Heavy Duty Type)

-

Vacuum Drying Chambers

Vacuum Drying Chambers

-

Traditional Chinese Medicine Pill Machine (for Small Pills)

Traditional Chinese Medicine Pill Machine (for Small Pills)

-

Automatic Pill Packaging Line (Weighing and Wax Shell Packaging)

Automatic Pill Packaging Line (Weighing and Wax Shell Packaging)

-

Pipe Conveying System for Cutting Machine

Pipe Conveying System for Cutting Machine

-

Orbital Automatic Pipeline Welding Machine (FCAW/GMAW)

Orbital Automatic Pipeline Welding Machine (FCAW/GMAW)

-

Split Type Automatic Pipe Welding Machine (Ordinary Type)

Split Type Automatic Pipe Welding Machine (Ordinary Type)

-

Numerical Control Pipe Cutting Band Saw Machine

Numerical Control Pipe Cutting Band Saw Machine

-

Pipe Automatic Welding Machine (FCAW/GMAW)

Pipe Automatic Welding Machine (FCAW/GMAW)

-

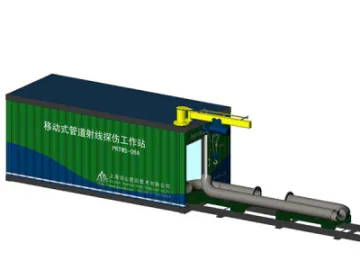

Piping Radiographic Test Work Station (Type-A)

Piping Radiographic Test Work Station (Type-A)

-

Automatic Piping Welding Workstation (Type-D)

Automatic Piping Welding Workstation (Type-D)

Hot Products