RFB560J/560/460J/460/360 Automatic Edge Banding Machine

The automatic edge banding machine contains several models including RFB560J, RFB560, RFB460J, RFB460 and RFB360. The main components are listed below, though not all of these items are installed on every model.

Touch Screen

The touch screen allows operators to carry out predetermined working procedures in a quick, simple and accurate way, while the operation interface is user-friendly.

Gluing Unit

The gluing unit is characterized by special glue spreading device and fast glue heating speed, and the precise gluing roller ensures that glue will be uniformly coated on a variety of materials.

End Cutting Unit

Our automatic edge banding machine takes advantage of the high-precision end cutting unit to cut off excessive edge banding from the leading and trailing ends, and this action is achieved with the help of two independent high-frequency motors. These motors are preinstalled in the linear guide rail, and each of them is equipped with copy attachment to realize accurate positioning.

Rough Trimming Unit

The rough trimming unit adopts the same design principle as the fine trimming unit does to get excellent processing result. Meanwhile, two high-frequency motors with individual power of 1.1kW work together with the rigid flat knife to realize strong cutting force.

Fine Trimming Unit

The fine trimming unit is applied by our edge banding machine to trim the top and bottom edges with the help of two independent high-frequency motors, and the tilting angle is adjustable within 45°C. This part adopts simple but steady design, and it allows convenient and accurate adjustment.

Scraping Unit

This scraping unit is used to remove cutting marks on the 3-mm-thick PVC or ABS edge banding, and the unpowered scraping system is on the basis of the high-rigidity structure. Meanwhile, the precise scraping action depends on the contour wheel.

Buffing Unit

Our automatic edge banding machine uses two independent motors for the purpose of cleaning and buffing after processing. This buffing unit possesses simple design and easy operation.

Comparisons Between Different Models

Technical Parameters

| Model | RFB-560J | RFB-560 | RFB-460J | RFB-460 | RFB-360 |

| Min. workpiece length (mm) | 120 | 120 | 120 | 120 | 120 |

| Min. workpiece width (mm) | 80 | 60 | 80 | 60 | 60 |

| Workpiece thickness (mm) | 10~60 | 10~60 | 10~60 | 10~60m | 10~60 |

| Band edging width (mm) | 12~65 | 12~65 | 12~65 | 12~65 | 12~65 |

| Band edging thickness (mm) | 0.4~3 | 0.4~3 | 0.4~3 | 0.4~3 | 0.4~3 |

| Feeding speed (m/min) | 12~20 | 12~18 | 12~20 | 12~18 | 12~18 |

| Input voltage (V) | 380 | 380 | 380 | 380 | 380 |

| Input frequency (Hz) | 50 | 50 | 50 | 50 | 50 |

| Output frequency (Hz) | 200 | 200 | 200 | 200 | 200 |

| Total power consumption (kW) | 14.5 | 12 | 14.5 | 9 | 9 |

| Required air pressure (Pa) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Overall dimensions (L×W×H, mm) | 5397×1370×1600 | 4870×1370×1600 | 4994×1370×1600 | 4480×1370×1600 | 3930×1370×1600 |

Related Names

Medium Ensity Fiberboard Edgebander | Wood Lathe | Woodworking Tool

Links:https://globefindpro.com/products/82517.html

-

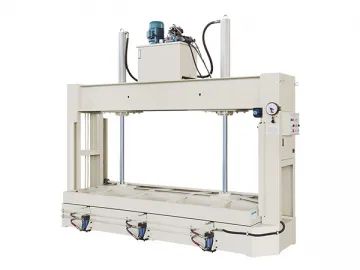

RRY4×8/100-3, 120-3 Heated Veneer Press

RRY4×8/100-3, 120-3 Heated Veneer Press

-

RCP260A/310A Veneer Cutting Machine

RCP260A/310A Veneer Cutting Machine

-

RCQ48C Double-end Cutting Saw

RCQ48C Double-end Cutting Saw

-

RBL2500B Glass Washing Machine

RBL2500B Glass Washing Machine

-

RBF300C-II Profile Wrapping Machine

RBF300C-II Profile Wrapping Machine

-

RX5117B Router

RX5117B Router

-

RBM503F/504F/505F/506F Planer

RBM503F/504F/505F/506F Planer

-

RLY300 Cold Veneer Press

RLY300 Cold Veneer Press

-

PVC Edge Banding

PVC Edge Banding

-

RTJ2325B Table Saw

RTJ2325B Table Saw

-

RMD127B Automatic Circular Saw Blade Grinder

RMD127B Automatic Circular Saw Blade Grinder

-

RXPQ400 Automatic Profile Spraying Machine

RXPQ400 Automatic Profile Spraying Machine